Custom Conveyor Systems | Webb-Stiles Products

Webb-Stiles designs and manufactures custom conveyor systems and material handling solutions tailored to your operation. Our in-house engineering team builds every system for long-term performance and reliable uptime—because we know every delay on your floor costs you money. That’s why we don’t just build systems—we help you stay running.

Additionally, the team develops fully integrated turnkey lines alongside overhead conveyors and CDLR systems. These solutions not only support both heavy-duty and medium-duty applications with lasting reliability—they also enhance workplace safety and improve ergonomics by reducing manual handling and repetitive motion.

Not sure which system you need? We’ll help you engineer the right solution.

Explore our Custom Conveyor Systems

Click any image to see how Webb-Stiles designs, builds, and installs systems that move your workflow forward.

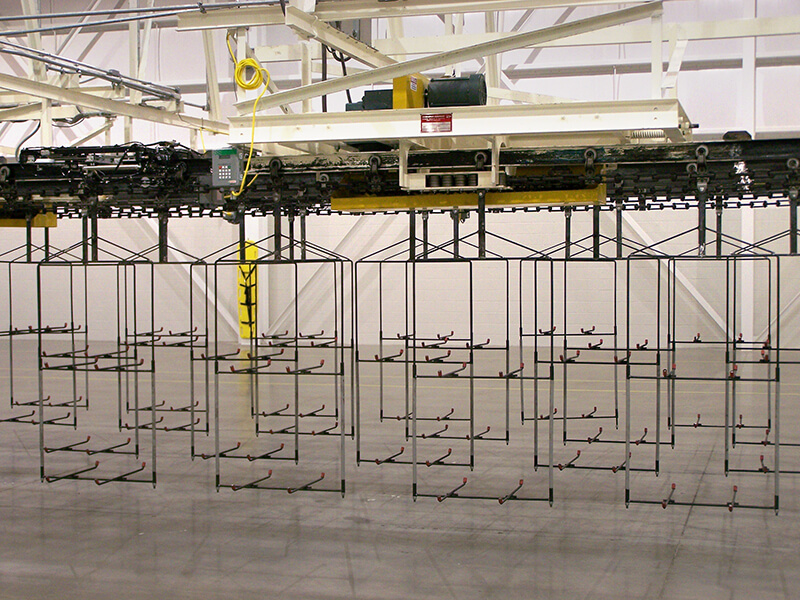

Overhead Conveyors

Overhead conveyor systems include monorail and power & free styles. They handle heavy loads in automotive, steel, and finishing environments. In addition, they move materials overhead with the flexibility to route, accumulate, and manage complex workflows.

Live Roller Conveyors

Live roller conveyors work well for pallet handling, assembly lines, and other industrial applications. The lineup includes chain-driven (CDLR), belt-driven (BDLR), and extended-range (ERLR) models. As a result, these conveyors provide strength, control, and long-term reliability.

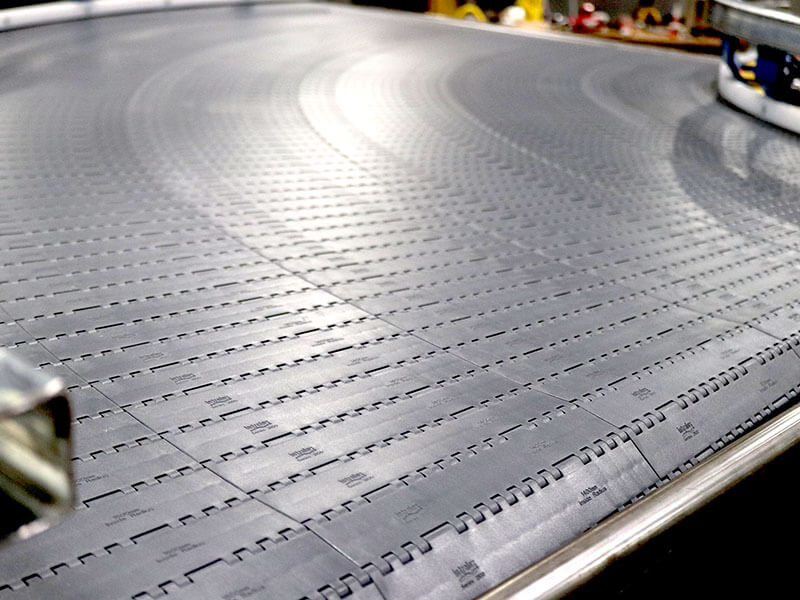

Belt Conveyors

Belt conveyors come in PVC, rubber, modular plastic, and wire mesh configurations. These designs support consistent product movement across packaging, assembly, and general material handling lines. For example, they help maintain efficient workflows for a wide variety of part sizes and shapes.

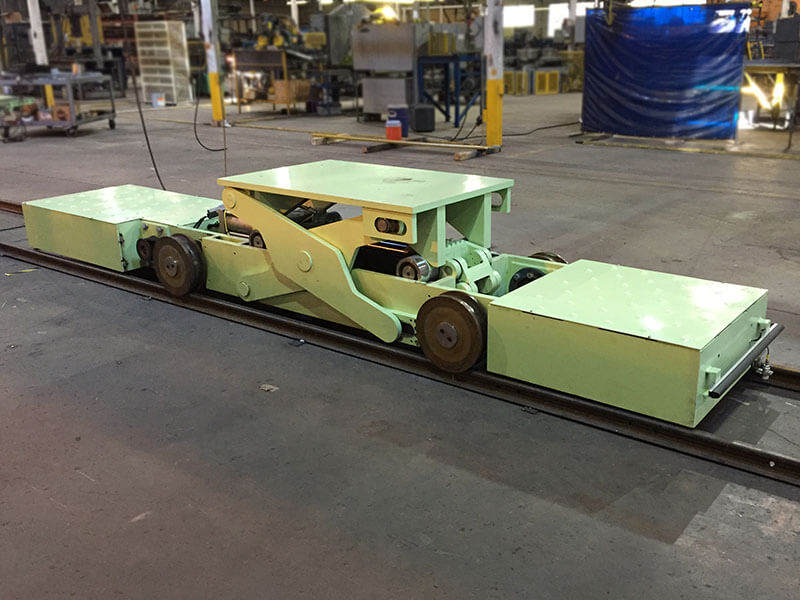

Transfer Systems

Transfer systems move products between conveyors or across multiple lines. Standard options include transfer cars, pop-up transfers, turntables, and shuttle systems. As a result, these solutions deliver smooth transitions, repeatable movement, and high-performance material handling—even for complex assemblies.

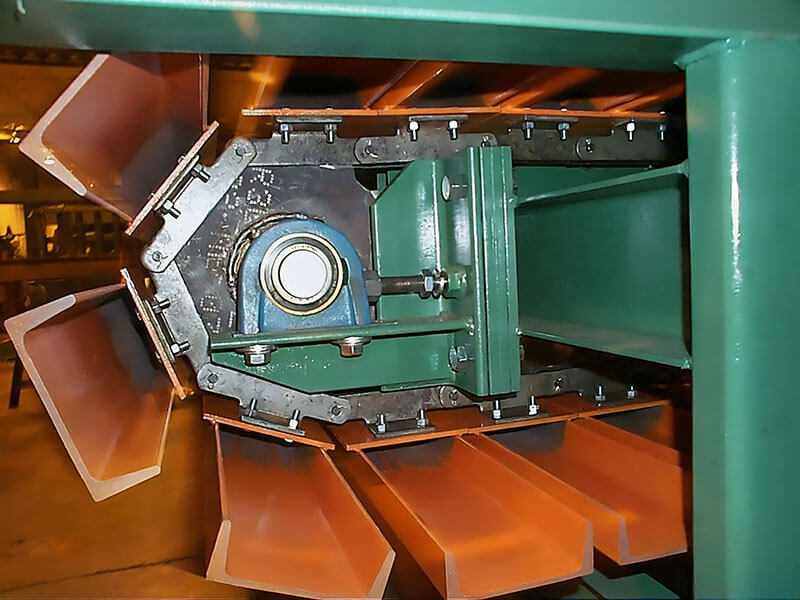

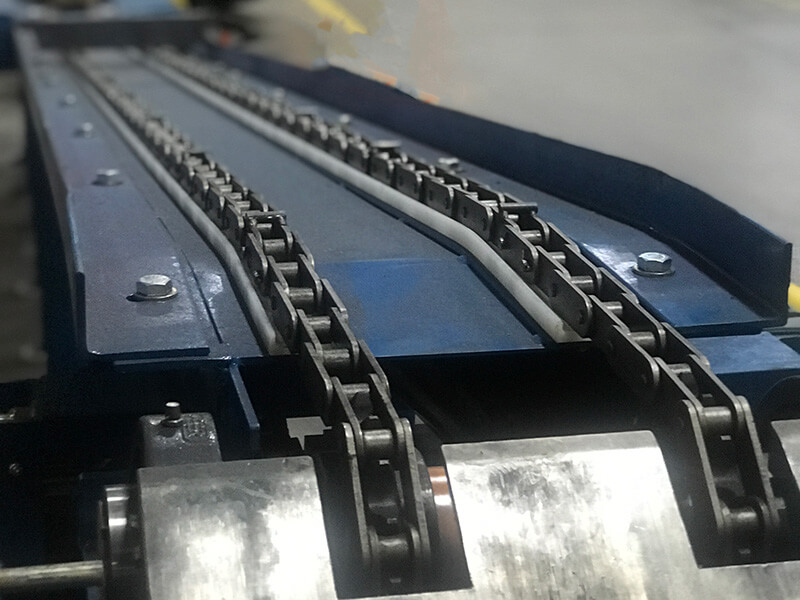

Chain Conveyors

Chain conveyors move heavy unit loads in manufacturing and assembly environments. Available styles include single-strand, multi-strand, and drag chain systems. Each design delivers smooth flow, strong durability, and seamless integration with other equipment. As a result, these systems work well for transporting pallets, fixtures, and steel components in high-demand settings.

Slat Conveyors

Slat conveyors perform well in tough environments where belt systems fail. With heavy-duty chains supporting steel or composite slats, these conveyors offer a stable surface for fixtures, molds, dies, and uneven products. Consequently, many operations in automotive, foundry, and finishing industries rely on them.

Vertical Conveyors

Vertical conveyors create space-saving paths for moving materials between levels. Systems include reciprocating lifts, continuous vertical conveyors, and high-speed “speed lifts.” These designs enable smooth transfer with precision and durability. In particular, they support high-throughput manufacturing, warehousing, and distribution workflows.

Towline Conveyors

Towline conveyors guide carts and fixtures through assembly, testing, and packaging zones. Their design supports ergonomic operation, heavy loads, and consistent movement across workstations. Because of this, they’re often used in automotive assembly, parts testing, and packaging environments that demand repeatable routes and operator safety.

Moving Floor Conveyors

Moving floor conveyors are designed for continuous movement of heavy loads in high-throughput environments. Using synchronized panels or slats, they provide level transport for castings, bulk parts, and large fabricated components. As a result, these systems are often used in foundries, automotive plants, and military applications.

Automated Storage & Retrieval Systems

Automated Storage and Retrieval Systems (ASRS) combine conveyor integration with vertical and horizontal storage solutions. System types include Elevated Transfer Vehicles (ETVs), vertical lifts, and indexing conveyors. This allows for space-efficient, high-throughput storage and retrieval in industrial and distribution facilities.

Highline Docks

Highline docks provide elevated access for conveyor loading and unloading. Often used with overhead, towline, or pallet systems, they offer safe operator access and precise material transfer. In addition, options include custom decking, safety rails, and integrated controls.

System Controls and Integration

System controls and integration services include PLC programming, HMI interfaces, and custom panel design. From basic on-off functions to fully automated logic with sensor coordination, these systems help ensure smooth, safe, and efficient operation. Additionally, they allow for tighter control of material flow across your facility.

Custom Engineered Systems

Custom engineered systems are designed from the ground up to match your layout, materials, and production flow. From initial concept to final installation, each system is tailored for seamless integration and reliable performance. Therefore, they’re ideal for meeting the needs of demanding production environments.

Auxiliary Equipment

Engineered to enhance your conveyor system, Webb-Stiles’ auxiliary equipment includes load handling devices, safety accessories, and structural components designed for seamless integration. From diverters to custom walkways, every solution supports your system’s performance and safety.

We Don’t Just Build Systems—We Build the Rollers Too.

Our in-house roller machine produces gravity, sprocketed, lineshaft, and overhead rollers to exact specs. One of our most requested parts—for a reason.

Want to know how these systems work in real-world settings? Follow Webb-Stiles on social media for project photos, behind-the-scenes content, and custom conveyor systems in action.