Auxiliary Conveyor Equipment by Webb-Stiles

Supporting, Controlling, and Enhancing System Performance

From load handling devices to structural supports and safety accessories, Webb-Stiles designs auxiliary equipment that ensures your conveyor system operates at peak efficiency. Whether it’s rotating, guiding, transferring, or stabilizing product flow, our auxiliary solutions are built to integrate seamlessly and keep your operation moving.

What is Auxiliary Equipment?

Auxiliary equipment refers to the essential components that support, control, and enhance a conveyor system’s performance. While primary conveyors handle the main task of moving products, auxiliary equipment ensures everything flows smoothly, safely, and efficiently.

These components perform specific functions like positioning loads, changing product orientation, merging or diverting traffic, and providing structural support. For example, devices such as rotators, upenders, and diverters help manage product direction and flow, while guide rails, decking, and bolsters add stability and safety to the system.

At a high level, auxiliary equipment works by integrating with your main conveyor line, either as inline modules or adjacent structures. They interact with products at critical points—rotating, lifting, transferring, or guiding items as needed—without disrupting overall system flow.

These solutions are ideal for manufacturing environments that require precise product control, heavy-duty load handling, or custom system configurations. Industries like automotive, appliance assembly, and industrial manufacturing often rely on auxiliary equipment to meet production demands and maintain safe, efficient operations.

Ultimately, auxiliary equipment is what transforms a basic conveyor into a complete material handling system—ensuring every product moves correctly, safely, and in the right orientation from start to finish.

Types of Auxiliary Equipment

Load Handling Devices

These devices manage product movement at critical points in your system. Whether it’s changing orientation, transferring between lines, or positioning items for the next process, load handling devices ensure products are where they need to be, how they need to be.

Examples include:

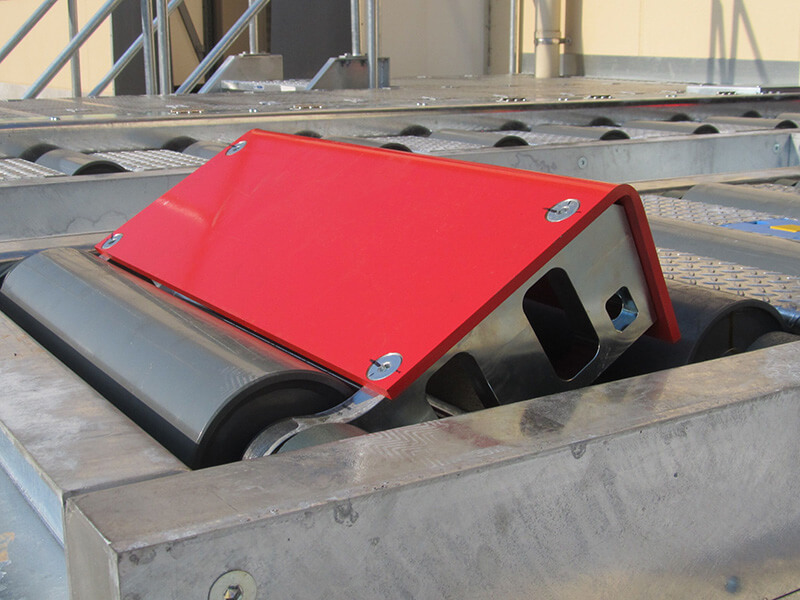

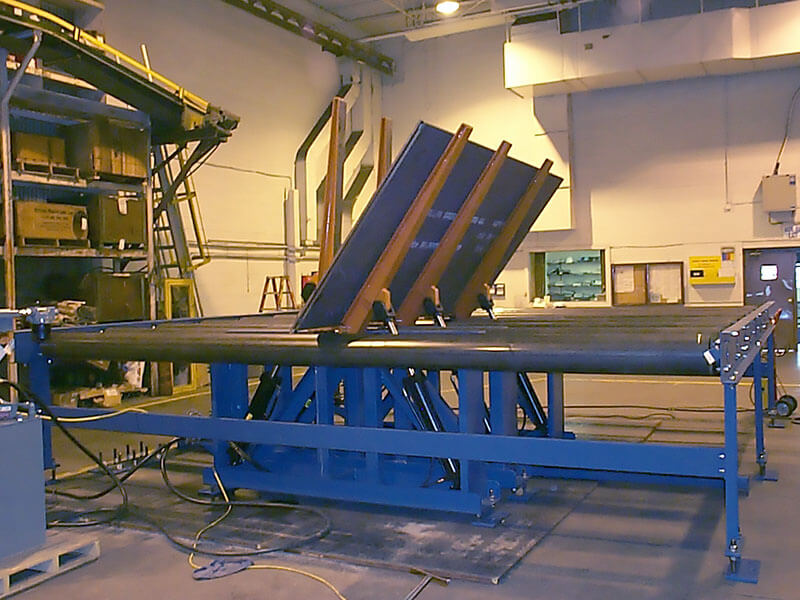

Diverters, rotators, upenders, pallet dispensers, stackers/destackers, and turnover devices.

Best for:

Applications requiring product repositioning, orientation control, or staged transfers, such as assembly lines, packaging systems, and heavy load handling.

Flow & Safety Accessories

Flow accessories keep products aligned, moving, and safe. These components control product direction, manage queueing, and protect both equipment and operators. Safety guards, guide rails, and indexing devices ensure smooth, compliant operations.

Examples include:

Guide rails, stops, clamps, wire mesh curves, pop-up stops, and indexing devices.

Best for:

Systems where precision flow control and operator safety are priorities, such as high-volume production lines, merge points, and load accumulation zones.

Structural & Support Components

Supporting components provide the physical foundation for your conveyor system. From full-tilt stands that allow maintenance access to custom decking and walkways, these structures ensure stability, accessibility, and long-term system reliability.

Examples include:

Full-tilt stands, adjustable supports, custom decking, walkways, workstations, bolsters, ball transfer tables, scales, and vibration feeders.

Best for:

Environments requiring custom-fit structural solutions, operator access, or load stabilization for heavy-duty applications.

Why Auxiliary Equipment Matters

A conveyor system isn’t complete without the right support. Auxiliary equipment fills the gaps between moving product from Point A to Point B and doing it efficiently, safely, and precisely. Here’s why auxiliary components are critical to a successful system:

Enhancing Workflow Efficiency

Auxiliary devices like diverters, transfers, and rotators streamline product flow. They reduce manual handling, eliminate bottlenecks, and keep your system moving without interruption.

Improving Product Control

From guide rails to upenders, auxiliary equipment ensures every product is aligned, positioned, and oriented correctly. This precision reduces errors, protects product quality, and supports downstream processes.

Protecting Operators and Equipment

Safety accessories such as stops, clamps, and protective barriers prevent accidents and protect valuable equipment. They create safer interaction points where operators and machinery meet.

Supporting Custom System Integration

Every facility has unique needs. Auxiliary components like decking, walkways, and bolsters allow your system to adapt—whether it’s supporting heavy loads or providing access for maintenance and inspection.

Adding Long-Term Value

With auxiliary equipment, your conveyor system becomes more than a transport line. It becomes a purpose-built solution, capable of adapting to changes in production demands while maintaining high performance.

Auxiliary Equipment in Action

Video Gallery

Want to see more? Hover over the video area and use the arrows or dots below to explore additional equipment in action.

Integrated Solutions by Webb-Stiles

At Webb-Stiles, auxiliary equipment isn’t an afterthought. It’s an essential part of every system we design.

Rather than treating auxiliary devices as bolt-ons, we engineer them to work seamlessly with your conveyor lines, ensuring smooth transitions, reliable product handling, and safe operator interaction.

Custom-Fit for Your Operation

Every facility has unique challenges. Whether you need a rotator for large assemblies, a flow control solution for complex merges, or walkways for safer maintenance access, we design auxiliary equipment that fits your specific layout and production needs.

Built for Demanding Environments

Our auxiliary components are designed to withstand heavy use, support precise load handling, and maintain performance in even the most demanding industrial environments. From automotive plants to distribution centers, we build solutions that last.

Expertise You Can Rely On

With decades of experience in custom material handling systems, Webb-Stiles guides you through every step—from concept and design to fabrication and installation. Our integrated approach ensures every component, including auxiliary equipment, delivers the performance you expect.

Let’s Build the Right Solution for You

Auxiliary equipment is what turns a good conveyor system into a great one. Whether you need better product control, safer operations, or a fully integrated solution, Webb-Stiles is ready to design the right equipment for your application.

Contact us today to talk about your next project.