Conveyor Inspection Analysis for Overhead Conveyor Systems – Now Available

Gain actionable system data through real-time strain gauge testing and mechanical inspection.

What is an Inspection Analysis?

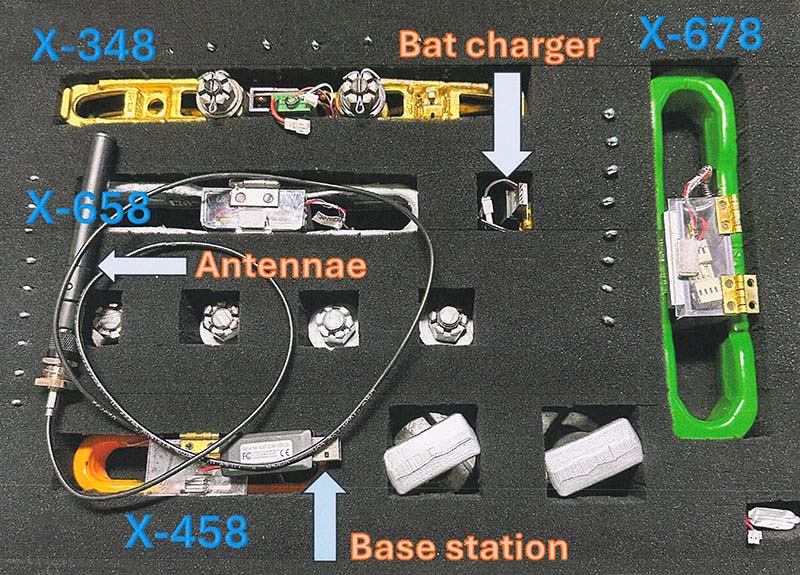

Inspection Analysis combines in-motion strain gauge testing with a physical inspection of key overhead conveyor components. Using a wireless strain gauge trolley link—sized for your 3″, 4″, or 6″ conveyor—the system captures chain pull forces under live load conditions as the line runs.

As the strain link collects force data, Webb-Stiles personnel inspect the structure, drives, and support framework to identify performance issues that visual observation alone might miss.

This process delivers a data-backed snapshot of system tension and stress points to uncover potential causes of misalignment, binding, or wear.

The service includes the ability to generate CSV files and Excel graphs of the test results. For each new test, engineers can review the data to confirm proper application.

How Inspection Analysis Works

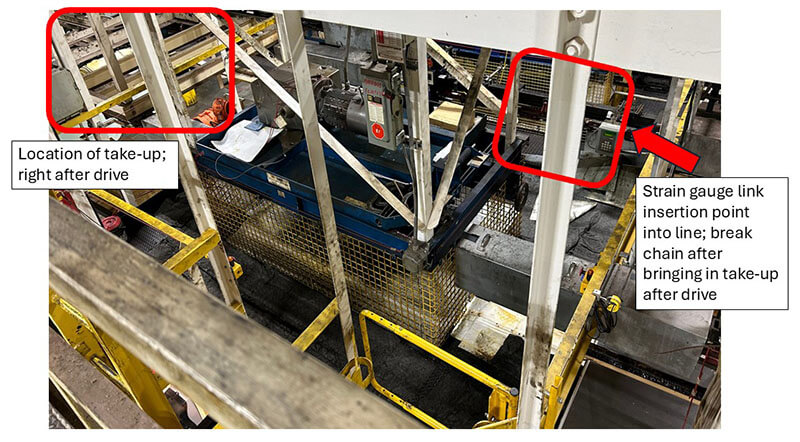

1. Strain Gauge Link Installed

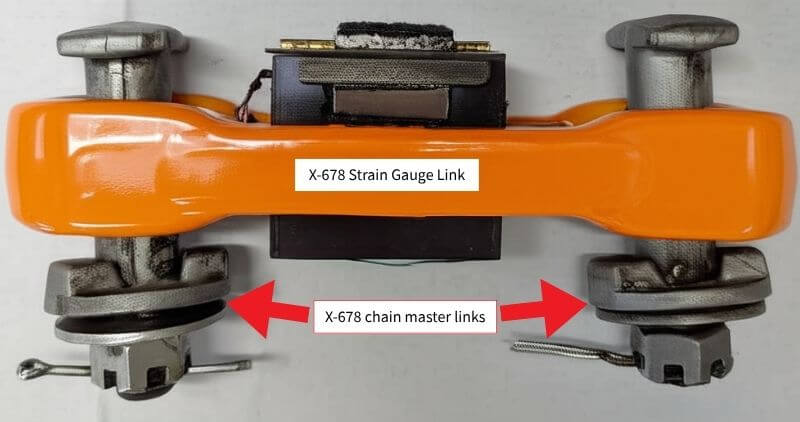

A wireless strain gauge link—matched to your chain size (X-348, X-458, X-658, or X-678)—is inserted into the overhead conveyor.

2. System Runs Under Normal Load

As the system runs, the strain link measures real-time chain pull along the full circuit. An internal transmitter stores the data.

3. On-Site Structural & Mechanical Review

While the link collects data, Webb-Stiles personnel inspect the drive units, track, supports, and carriers to identify visible stress points or wear.

4. Data Download & Analysis

After completing the test run, the team removes the link and downloads the data via USB. Results are converted into CSV and Excel graphs for engineering analysis.

5. Recommendations Developed

Engineering staff review the combined data—force readings and field observations—and develop actionable insights with prioritized recommendations to address root causes.

This dual-layer approach pinpoints issues like excessive tension, misalignment, or worn components before they lead to system failure or downtime.

Why Test Your System?

Identify wear points and potential failure areas

Catch stress concentrations or problem zones before they lead to downtime or equipment damage.

Enhance system design and engineering

Evaluate performance under live load to inform future upgrades or redesigns.

Improve preventative maintenance planning

Use data-driven insights to schedule maintenance more effectively and reduce unexpected interruptions.

Gain actionable data to drive smarter upgrades

Make confident improvement decisions based on real-time feedback and field-verified measurements.

Ensure safe, long-lasting operation

Confirm that chain pull and structural loads stay within safe operating limits.

Reduce downtime and costly repairs

Spot emerging issues early to avoid unplanned shutdowns and major component replacements.

Validate system performance under live load

Confirm that your conveyor is functioning as intended during actual operation—not just when idle.

Uncover hidden stress points before they become failures

Strain testing reveals issues that may not be visible during idle inspection or routine maintenance.

What We Deliver

Every Inspection Analysis includes a combination of real-time data collection and on-site evaluation. Here’s what you receive as part of the service:

-

Strain Gauge Testing & Rail Wear Checks

Wireless strain links measure chain pull and detect abnormal force patterns. Technicians also inspect the rail for visible signs of wear. -

Temperature & Vibration Monitoring

Targeted checks are performed on motors, gearboxes, and drive components to identify heat or vibration signatures that signal mechanical issues. -

Structural Inspection

Support beams, weld points, and mounting brackets are visually reviewed for fatigue, damage, or misalignment. -

Data Output & Engineering Review

Recorded data is downloaded, converted into Excel graphs, and reviewed for trends, spikes, or anomalies. -

Root Cause Analysis

Our team correlates the data with field observations to pinpoint the source of performance issues. -

System Recommendations

You receive a clear, prioritized list of suggested repairs, adjustments, or upgrades based on the findings

Want to Know How Your System Performs Under Pressure?

Inspection Analysis gives you real data—not guesses—about how your overhead conveyor is really operating. From tension spikes to structural fatigue, we help uncover issues others might miss.

Smarter Testing.

Stronger Systems.

Looking for full overhead conveyor solutions? Explore our Overhead Systems.