Belt Conveyors by Webb-Stiles

What is a Belt Conveyor?

Belt conveyors are one of the most common and versatile solutions for moving products through a facility. They use a continuous belt surface to carry items from one point to another, providing smooth and reliable transportation for a wide range of materials.

At its core, a belt conveyor loops a belt around a series of pulleys. The drive pulley actively powers the belt, moving products along the conveyor’s length. Depending on the application, the belt may glide over a flat slider bed or roll across supporting rollers beneath it.

Many choose belt conveyors for their simplicity, gentle handling, and adaptability. While they excel at transporting items with flat or firm bottom surfaces, they can also be customized with cleats, textured belts, or side guards to manage more challenging products.

Furthermore, belt conveyors are particularly effective in applications involving elevation changes, continuous product flow, or situations where product stability is essential. Common examples include assembly lines, packaging areas, feeding furnaces in foundries, and moving products between workstations or processes.

Unlike systems that rely on friction rollers or chains, belt conveyors offer nearly limitless configuration possibilities. Options include various belt materials (such as PVC, fabric, modular plastic, or wire mesh), bed types (slider bed or roller bed), incline and decline sections, curves, and flexible drive placements—all tailored to meet specific project needs.

History of Belt Conveyors

Belt conveyors are among the most recognized and widely used types of material handling equipment. Their history dates back to the late 19th century, when simple belt systems moved bulk materials in mining and agriculture. Early versions often featured leather or canvas belts running over wooden or steel rollers, powered by hand cranks, water wheels, or steam engines.

A major turning point came in 1901, when Swedish company Sandvik invented and began producing steel belt conveyors for transporting bulk materials. This innovation significantly improved durability and efficiency, laying the groundwork for modern conveyor technology.

As industrial production expanded through the early 20th century, belt conveyors became essential for moving goods efficiently through factories, warehouses, and distribution centers. Their ability to handle a wide range of products—from small packages to heavy bulk materials—solidified their role in material handling operations.

Over time, continuous improvements in materials, design, and drive technologies further advanced conveyor performance. Today, belt conveyors are used in nearly every industry, supporting applications from manufacturing and logistics to food processing and packaging.

Types of Belt Conveyors

Webb-Stiles engineers belt conveyors in a wide range of configurations, each designed to match specific material handling needs. Below are the most common types we build—and when each style is the right fit.

Slider Bed Belt Conveyor

A slider bed belt conveyor moves products using a belt that glides over a flat steel surface. This simple design lowers costs and reduces maintenance by eliminating rollers beneath the belt.

Why it’s valuable: Its straightforward design ensures reliable, continuous movement of lightweight to moderate loads, especially in clean, controlled environments.

When it’s used: Companies choose slider beds when smooth, consistent transport is needed without requiring high speeds or heavy load capacity.

Best for: Streamlined processes, general product handling, and low-maintenance environments.

Cleated Belt Conveyor

A cleated belt conveyor uses raised sections (cleats) attached to the belt surface. These cleats hold products in place, preventing them from sliding backward on inclines or declines. Additionally, cleats help space items apart for better product control.

Why it’s valuable: Cleated belts provide reliable transport of items that might otherwise slip, roll, or bunch together—especially when moving up or down steep angles.

When it’s used: This style is selected when products must travel on inclines or declines, or when precise spacing and separation are critical to the process.

Best for: Incline/decline applications, loose product transport, and controlled product spacing.

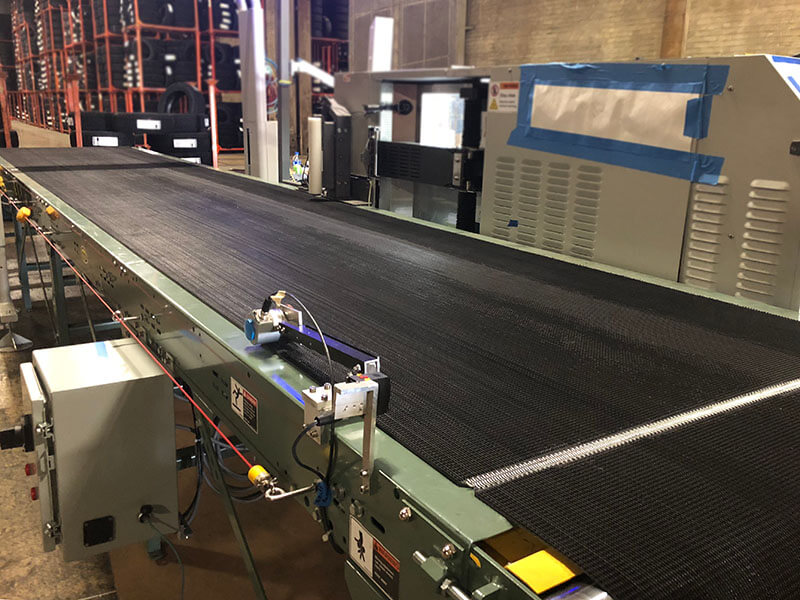

Wire Mesh Belt Conveyor

Wire mesh belt conveyors feature a woven metal belt surface that allows air, water, or heat to pass through while moving products. This open design supports processes like cooling, drying, or washing during transport.

Why it’s valuable: Wire mesh belts withstand high temperatures and harsh conditions, making them ideal for environments where product exposure to heat, drainage, or airflow is essential.

When it’s used: Companies choose wire mesh belts for applications involving heat-treated materials, washing processes, or when airflow during conveyance is required.

Best for: Heat-treated materials, cooling lines, and parts washing systems.

Roller Bed Belt Conveyor

A roller bed belt conveyor moves products on a belt supported by a series of rollers. These rollers minimize friction between the belt and the frame, allowing heavier loads to move more efficiently with less wear.

Why it’s valuable: By reducing friction, roller beds improve energy efficiency, extend conveyor life, and support faster speeds or longer runs compared to slider beds.

When it’s used: This style is selected for applications handling heavier products, longer distances, or higher throughput—without sacrificing durability.

Best for: Heavy-duty applications, high-speed movement, and extended conveyor runs.

Modular Plastic Belt Conveyor

A modular plastic belt conveyor uses interlocking plastic segments to create a durable, flexible conveying surface. This segmented design simplifies repairs, allows tight turning radii, and provides open areas for drainage or washdown processes.

Why it’s valuable: Modular belts resist wear, require less maintenance, and excel in environments where frequent cleaning or high durability is necessary.

When it’s used: This style is ideal for systems facing wet, abrasive, or high-load conditions, as well as layouts with tight curves or elevation changes.

Best for: Washdown duty, tight curves, and high-wear environments like manufacturing or industrial processing.

Troughing Belt Conveyor

A troughing belt conveyor uses angled rollers beneath the belt to shape it into a “U” or trough profile. This design keeps loose or granular materials centered and contained during transport.

Why it’s valuable: The trough shape prevents spillage and maintains stable movement of bulk materials over long distances, improving process reliability.

When it’s used: Companies select this style for applications handling large volumes of loose material, where containment and spill prevention are critical.

Best for: Bulk material handling, spill containment, and foundry feed applications.

Applications & Uses

Belt conveyors are widely used across industries for their versatility, smooth product handling, and ability to manage elevation changes. Below are common environments where belt conveyors are the preferred choice—and why.

Assembly & Production Lines

-

Moves products between workstations with controlled speed and spacing.

-

Provides a stable surface for assembling appliances, automotive components, and industrial parts.

-

Supports flexible layouts with straight, curved, and inclined sections.

Packaging, Sorting & Rework

-

Transfers products through pack-out, inspection, labeling, and sorting stations.

-

Handles tray re-entry and reject processes with forward/reverse operation.

-

Allows for product spacing and accumulation using cleated or modular belts.

Elevation Changes & Transfers

-

Moves products between elevation levels or process zones.

-

Incline and decline conveyors with cleats prevent rollback on steep angles.

-

Common for transitions from assembly to shipping or between operations.

Heavy Material & Industrial Processing

-

Troughing conveyors handle bulk materials like sand, castings, and foundry feeds.

-

Wire mesh belts withstand heat and abrasion in harsh environments.

-

Supports industrial parts washing, cooling lines, and in-process material treatment.

Key Features

Webb-Stiles belt conveyors are engineered for reliability, flexibility, and performance across a wide range of applications. Below are the key features that define their capability.

Load Handling & Capacity

-

Supports light to heavy-duty loads, sized per application.

-

Handles product handling, tray movement, and bulk materials.

-

Cleated belts and troughing designs increase load containment and control.

Performance in Demanding Applications

-

Built to withstand abrasive, high-impact, and high-temperature conditions.

-

Wire mesh and modular belts resist heat and wear in foundry and heavy-duty use.

-

Supports incline, decline, and curved layouts for elevation changes and tight spaces.

-

Guarding options protect operators from pinch points and overhead return rolls.

Belt Materials & Styles

-

PVC (two-ply, three-ply) in various thicknesses for general use.

-

Rough top belts for added friction on inclines.

-

Modular plastic belts for durability in abrasive environments.

-

Wire mesh belts for high-temperature and industrial processing.

-

Cleated belts for spacing, product separation, and incline stability.

Custom Engineering & Support

-

Every system designed per project—not off-the-shelf models.

-

Integrates with customer-supplied controls and sensors.

-

Adjustable supports allow on-site height changes.

-

Installation supervision and engineering assistance available.

How Belt Conveyor Systems Are Engineered

No two belt conveyors are exactly alike. Each system is engineered to match the specific materials, processes, and environments it will serve. At Webb-Stiles, we lead every project through a thoughtful design process, ensuring the conveyor fits the application—not the other way around.

The Product Drives the Design

Design begins with understanding what you’re moving. Product size, weight, shape, and stability influence belt material, support structure, and traction methods. For instance, lightweight products may glide smoothly on a slider bed, while heavier or irregular loads often require roller beds or cleated belts for added control.

Fitting the Process Flow

Next, the conveyor must integrate seamlessly with the overall process layout. Whether climbing to a mezzanine, navigating a tight curve, or reversing for a reject line, these requirements shape the system’s configuration. Inclines, declines, and turns are carefully designed to maintain smooth product flow without disrupting operations.

Handling the Environment

Industrial settings bring unique challenges. Foundries, for example, demand belts that can withstand heat, abrasion, and heavy impact. In these cases, Webb-Stiles specifies wire mesh or heavy-duty modular belts for durability. Additionally, guarding is incorporated to protect operators from pinch points and overhead return rolls.

Drives, Controls, and Flexibility

Drive systems are selected based on the required speed and load for each application. Some situations call for fixed-speed drives, while others benefit from variable frequency controls for greater precision. Importantly, Webb-Stiles ensures every conveyor integrates with existing automation for a seamless fit.

Mounting and Support Solutions

Space constraints, floor loading, and accessibility also influence conveyor design. Adjustable supports allow for on-site installation flexibility, while overhead mounting solutions help free up valuable floor space. Every support structure is engineered to provide both stability and ease of maintenance.

Webb-Stiles Leads the Process

At Webb-Stiles, we don’t offer cookie-cutter solutions. Instead, we approach each project as a true partnership. By asking the right questions and providing in-house engineering expertise, we guide our customers through design, fabrication, and installation. The result is a belt conveyor system built for long-term performance in the real-world environment it serves.

Downloads & Literature

For more information on Webb-Stiles belt conveyor systems, download the following resource:

Let’s Talk About Your Belt Conveyor Project

Whether you’re moving light products through an assembly line or handling heavy loads in a demanding environment, Webb-Stiles can help engineer the right belt conveyor system for your needs. Contact our team to start the conversation—we’ll guide you through every step of the process.