History of Conveyor Systems

The history of conveyor systems shows how these essential tools have evolved over a century of industrial innovation.

An Overview of Conveyor System Evolution

Conveyor systems have been essential in material handling for over a century. These systems continuously evolve to meet the changing needs of industries worldwide. The earliest conveyors were simple solutions for moving goods over short distances, using manual tracks or basic belt systems. As industries grew, production demands increased, making more efficient and automated solutions necessary.

A major breakthrough came during the Industrial Revolution. Early conveyor systems, such as overhead cranes and gravity-fed conveyors, were introduced to improve material movement. Though rudimentary, these systems formed the foundation for the sophisticated material handling technology we rely on today.

Over time, belt conveyors revolutionized bulk handling. Chain conveyors and live roller conveyors improved the transportation of heavier, more complex loads. As automation and control systems advanced, conveyors became smarter, faster, and more adaptable. This evolution transformed industries like automotive manufacturing, food processing, and logistics.

Today, conveyor systems do more than move materials. They are vital to production efficiency, helping manufacturers automate processes, reduce labor costs, and increase throughput. Ongoing innovation in custom-engineered solutions keeps conveyor systems at the heart of industrial progress. Understanding the history of conveyor systems explains their critical role in modern automation.

The Origins of Conveyor Systems

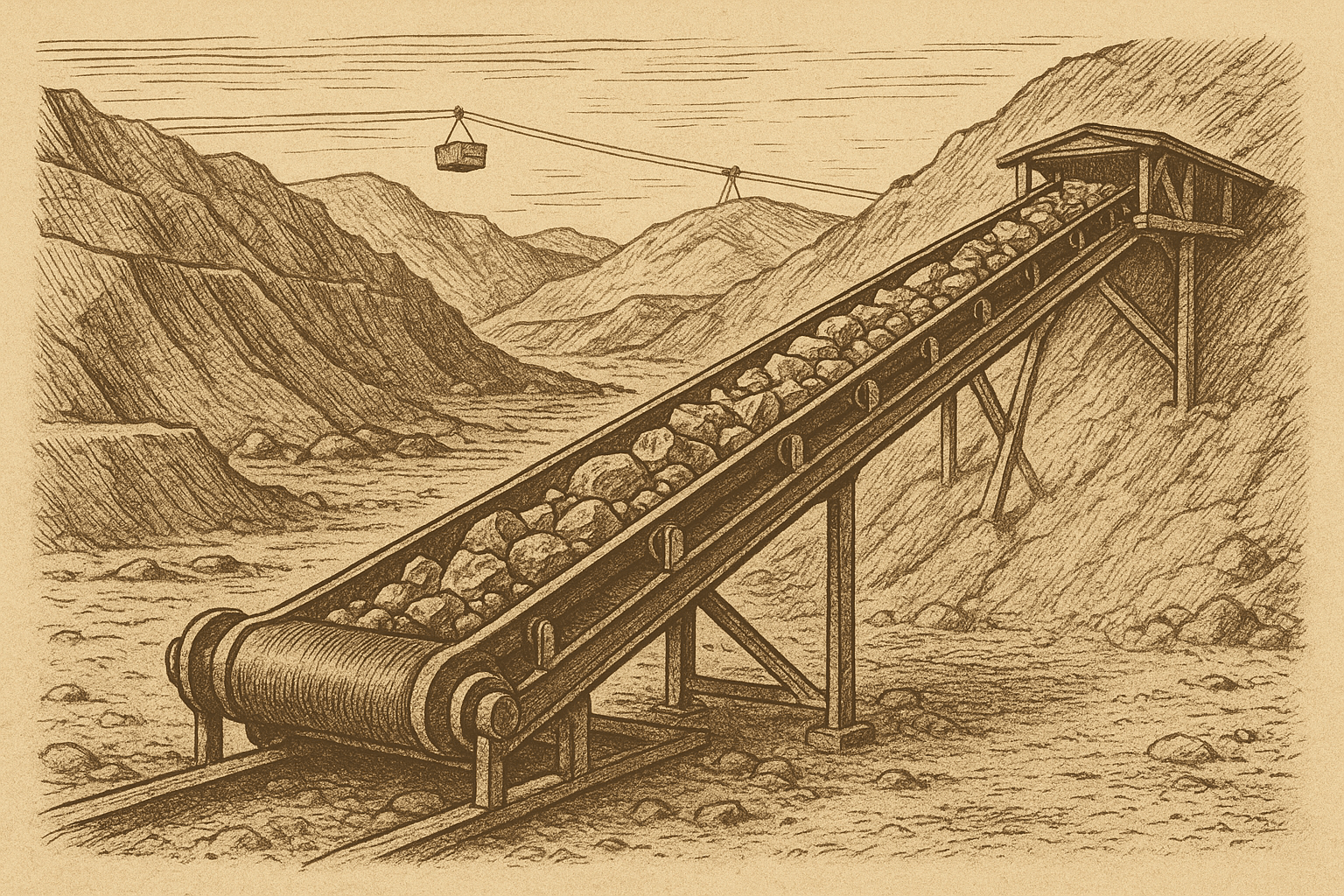

The history of conveyor systems began in the late 19th century as industries searched for better ways to move materials across growing factory floors. Early methods, like manual carts and pulley systems, were slow and labor-intensive. As mining, agriculture, and manufacturing expanded, so did the need for more effective material handling solutions.

Belt conveyors were first used on a large scale in the mining industry. They transported coal and ore over long distances, reducing manual labor and boosting productivity.

Around the same time, overhead cranes appeared in factories to handle heavier loads such as steel and machinery parts. These early conveyor designs focused on moving large, bulky items that couldn’t be handled manually. Their impact was especially valuable in industries like construction and heavy manufacturing.

This image was generated using ChatGPT

Early Conveyor Development in Industry

In the late 19th century, conveyor systems began to emerge as essential tools for industrial automation. Industries like mining, grain milling, and agriculture needed faster, more efficient ways to move materials. Early conveyors were basic manual systems using simple belts or tracks. Despite their simplicity, these systems were revolutionary, dramatically speeding up material movement in factories and warehouses.

The mining industry was the first to adopt belt conveyors on a large scale. They transported bulk materials like coal and ore over long distances, reducing manual labor and increasing productivity.

At the same time, factories began using overhead cranes to handle heavier materials such as steel and machinery parts. These early conveyor designs focused on moving large, bulky items that couldn’t be transported by hand. As a result, they became invaluable in industries like construction and heavy manufacturing.

This image was generated using ChatGPT

Industrialization and the Rise of Conveyor Systems

As the Industrial Revolution gained momentum in the late 19th century, industries faced growing demands for faster and more efficient material handling. Factories and production lines expanded rapidly, outpacing the capabilities of manual labor and basic pulley systems.

This period marked a turning point for conveyor systems. Early designs, such as overhead cranes and simple belt systems, were adapted to streamline production. Belt conveyors became especially important for industries like mining, grain handling, and agriculture, where they efficiently transported bulk materials over long distances.

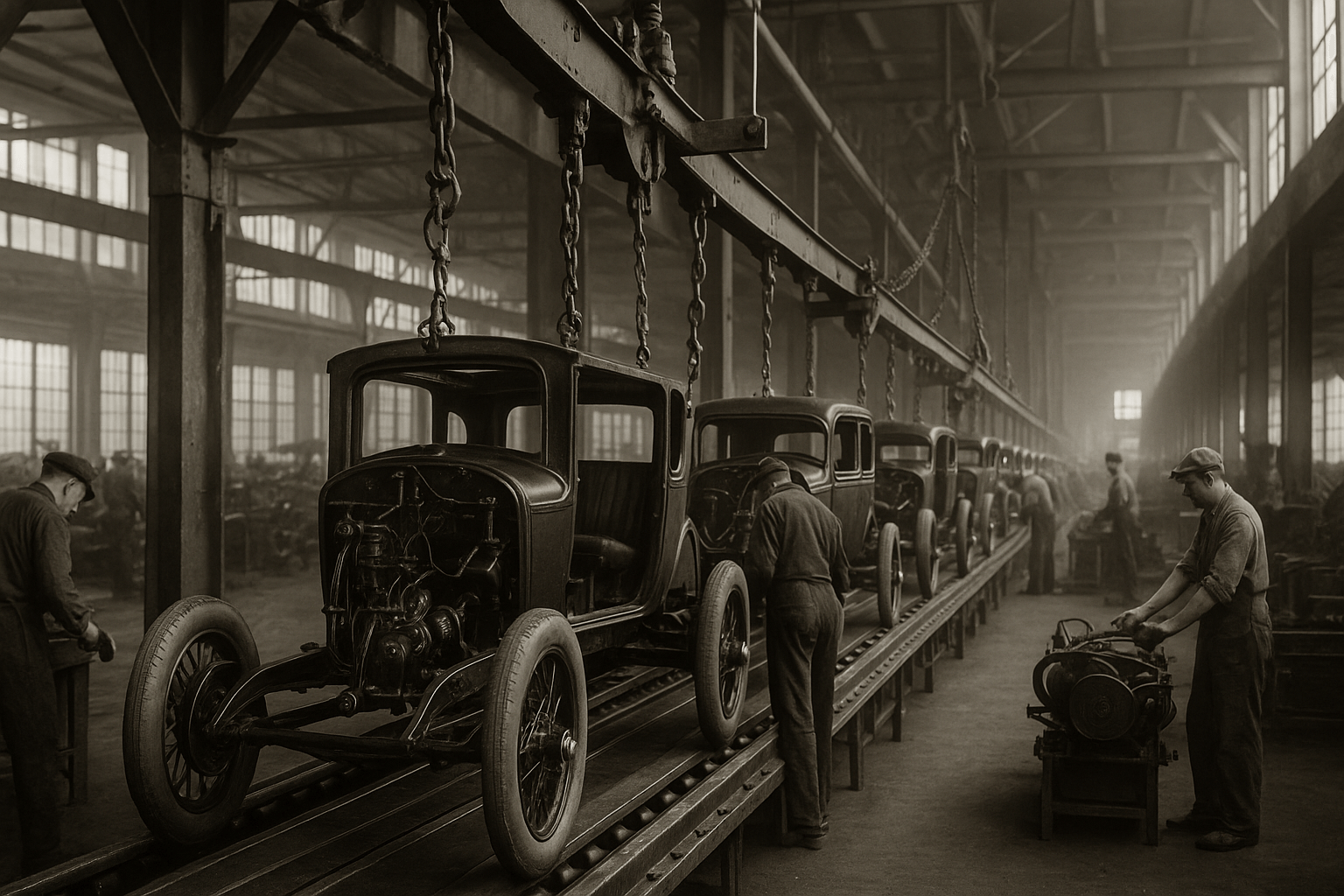

In 1913, Henry Ford revolutionized manufacturing by integrating conveyor systems into his automotive assembly line. Powered by overhead conveyors, Ford’s moving assembly line reduced car assembly time from hours to just a fraction of the original process. This innovation dramatically lowered production costs and reshaped the manufacturing industry.

Ford’s approach wasn’t only about efficiency. He transformed factory workflows by bringing the product to the worker, rather than moving workers around the assembly floor. This shift improved consistency, reduced costs, and significantly increased production speed.

Ford’s success sparked widespread adoption of overhead conveyors across multiple industries. As automation advanced, conveyors became central to modern manufacturing—from automotive plants to food processing, retail, and logistics.

Webb-Stiles: Leading the Change in Conveyor Solutions

With over 60 years of experience, Webb-Stiles has become a leader in custom-designed conveyor systems. While early conveyors laid the foundation for manufacturing, Webb-Stiles continues to push the boundaries of what’s possible in material handling today. From overhead conveyors to Power & Free systems, Webb-Stiles delivers tailored solutions to meet the needs of industries worldwide.

Our commitment to innovation, quality, and service ensures every system is engineered to meet the unique requirements of each customer. As industries evolve, Webb-Stiles stays at the forefront of custom conveyor engineering, creating the systems that will move businesses forward.

See how Webb-Stiles’ history of innovation continues on our Company History page.

Webb-Stiles Company

Headquarters. Valley City, Ohio

Webb-Stiles of Alabama

Southern Division. Gadsden, Alabama

Follow Webb-Stiles on social media to see how we continue advancing conveyor system innovation today.