Conveyor Rollers

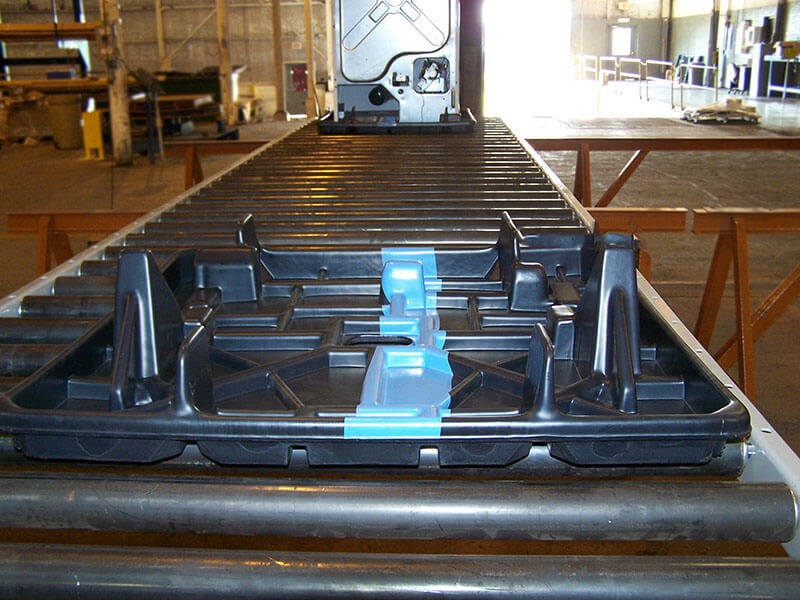

Whether you’re moving light packages or powering heavy-duty loads, conveyor rollers are the foundation of efficient material handling. From gravity-fed lines to motor-driven live roller systems, Webb-Stiles offers a full range of rollers engineered for performance, durability, and seamless integration.

Additionally, all rollers are manufactured in-house using our automated roll machine, ensuring consistent quality and total customization flexibility. Standard options are available in a wide range of diameters, gauges, and bearing types. For unique needs, custom configurations are built to meet the most demanding application requirements.

Looking for a specialty or oversized roller? Nevertheless, we build those in-house too—and every roller is proudly made in the USA.

Jump to:

Types of Conveyor Rollers

Gravity Rollers

Design & Operation:

Gravity rollers use a slight incline to move products without power. Each roller spins freely on bearings, as a result, items coast across the surface using natural force. Additionally, shafts are spring-loaded for quick replacement.

Key Benefits:

- Low cost, low maintenance

- Quiet and energy-free operation

- Simple to install and reconfigure

Applications:

-

Manual pick lines

-

Packaging and fulfillment

-

Warehouse transfer sections

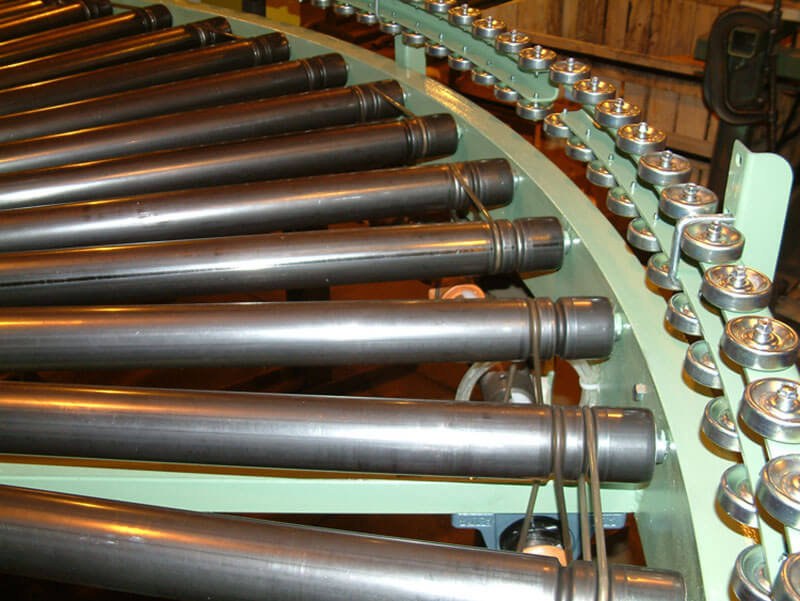

Sprocketed Rollers

Design & Operation:

Sprocketed rollers use fixed-position sprockets that engage with drive chains, ensuring consistent, positive movement. Consequently, they’re ideal for heavy loads, indexing, or powered transfer systems. Multiple sprockets and shaft styles are available.

Key Benefits:

-

High torque and load capacity

-

Reliable movement without slippage

-

Durable in harsh or dusty environments

Applications:

-

Chain Driven Live Roller (CDLR) systems

-

Vertical or robotic conveyors

-

Stop-start indexing or accumulation

Lineshaft Rollers

Design & Operation:

Lineshaft rollers are powered by a single shaft running beneath the conveyor. In addition, elastic bands drive individual rollers, enabling accumulation and gentle product handling. In short, they’re ideal for light to medium loads.

Key Benefits:

-

Safe and quiet operation

-

Low energy consumption

-

Accumulates without sensors or controls

Applications:

-

Order fulfillment

-

Manufacturing workstations

-

Distribution centers

Specialty Overhead Systems

Design & Operation:

Built in-house to your exact specifications using our automated roll machine. Specialty rollers include tapered, impact, grooved, oversized, bowtie, and motorized options—all precision-fit for your system layout and function. As a result, they support both standard and complex overhead designs.

Key Benefits:

-

Designed for unique loads or layouts

-

Engineered for integration with new or existing systems

-

Compatible with Webb-Stiles and competitor equipment

Applications:

-

Curved or vertical conveyors

-

Harsh load zones or robotic cells

-

Heavy-duty manufacturing and custom automation

Examples of Specialty Rollers

Custom 5″ Roller with Snap Ring Grooves

Welded in-house with precision grooves to retain bearings under high load conditions.

Vertical Sprocketed Roller for Robotic Application

Custom-built for vertical operation in a robotic painting carousel system.

CDLR Roller with Round Shaft and Welded Sprockets

Heavy-duty CDLR roller with a round shaft and welded sprockets for fixed drive engagement.

Key Features of Webb-Stiles Conveyor Rollers

Built to meet the demands of real-world material handling, our conveyor rollers combine strength, precision, and versatility. In short, from standard models to custom-engineered designs, every roller is manufactured in-house for consistent performance throughout your entire system.

Heavy-Duty Construction

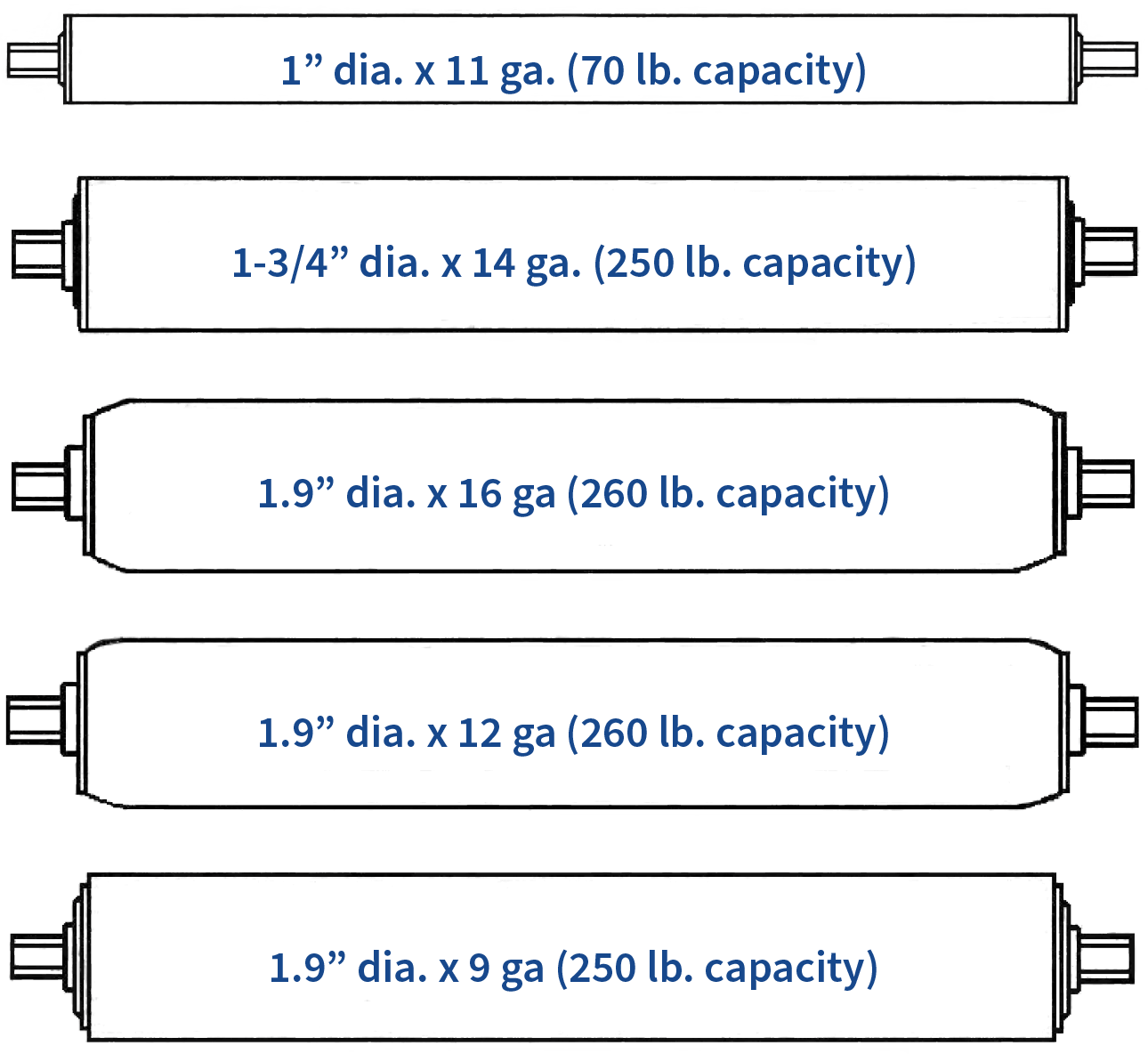

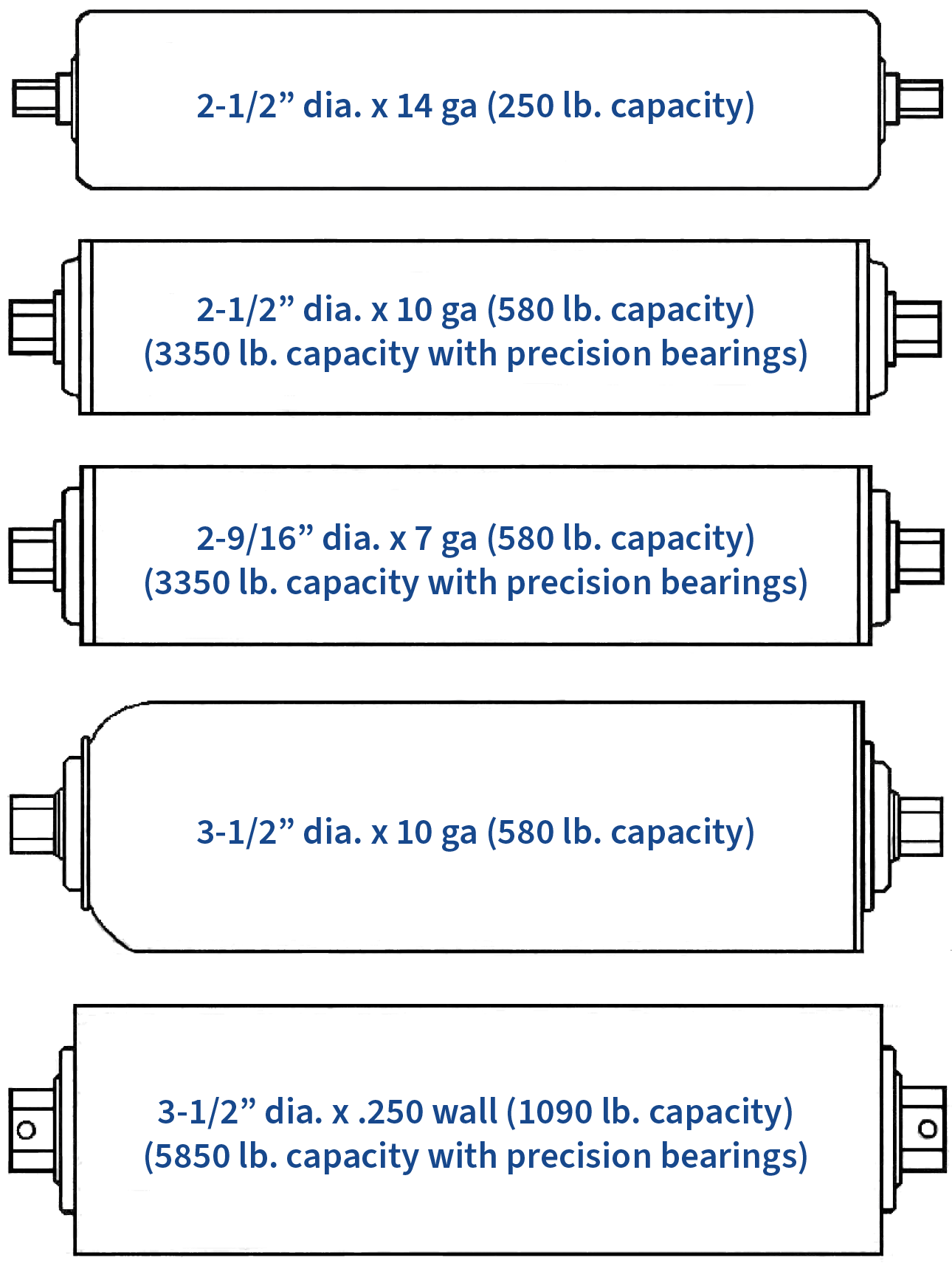

All rollers are built from heavy wall steel tubing, with ends reamed or swaged in-house for precision bearing fits. Standard models range from 1″ to 3.5″ in diameter and support loads up to 5,850 lbs. As a result, they’re well-suited for demanding applications. For example, many of our rollers are used in rugged environments like heavy equipment transfer lines.

Precision-Machined Shafts

Standard hex shafts are spring-loaded for easy tool-free installation. Optional round shafts and snap ring grooves are available for specialized applications. In addition, these options improve fit and alignment. That way, installations stay fast and consistent even in tight timelines.

Wide Bearing Selection

Choose from free-running, grease-packed, semi-precision, or precision bearings—each selected based on your speed, load, and environmental requirements. Ultimately, this flexibility ensures optimal performance in any setting. For example, free-running bearings are often chosen for light package handling, while precision bearings serve high-torque zones.

Urethane Sleeve Option

Increase grip and protect delicate products with urethane-coated rollers, available in multiple colors and friction ratings. Because of this, they’re ideal for sensitive handling zones. Even so, they remain compatible with most standard roller designs.

Noise-Reducing Hushveyor Option

Our exclusive Hushveyor rollers dampen high-frequency noise and reduce overall sound levels by up to 10 dB—without altering system layout or roller performance. As such, they support both safety and comfort.

Made In-House, Made in the USA

All standard and specialty rollers are manufactured at Webb-Stiles facilities using our automated roll machine for tight tolerances and consistent quality. That means every unit is built under the same process controls, no matter the size or configuration. What’s more, you don’t have to worry about third-party lead times or off-site delays.

Bearings Explained

The performance of a conveyor roller depends heavily on the bearing inside. Webb-Stiles offers a complete range of bearing styles to meet the needs of different systems—from manual push lines to high-torque, motorized conveyors.

Free-Running Bearings

Designed for low-resistance rotation, these bearings are ideal for gravity conveyors. They require no lubrication and allow products to move smoothly with minimal push force. Because of this, they’re a reliable choice for quiet, low-maintenance systems.

Best For:

-

Gravity-fed lines

-

Low-maintenance systems

-

Quiet, efficient movement

Grease-Packed Bearings

Sealed and lubricated for life, these bearings offer long-lasting performance under higher loads and speeds. As a result, they’re the standard in most live roller and chain-driven conveyors.

Best For:

-

CDLR and LSLR systems

-

Belt-driven applications

-

Dirty or high-moisture environments

Precision & Semi-Precision Bearings

For demanding or specialty applications, precision and semi-precision bearings offer tighter tolerances, higher load ratings, and smoother operation. In these cases, performance and control are critical.

Best For:

-

High-speed or high-load conveyors

-

Powered accumulation zones

-

Custom or robotic integration

Need help choosing the right bearing? Our team can help specify the best option based on your speed, load, and operating environment.

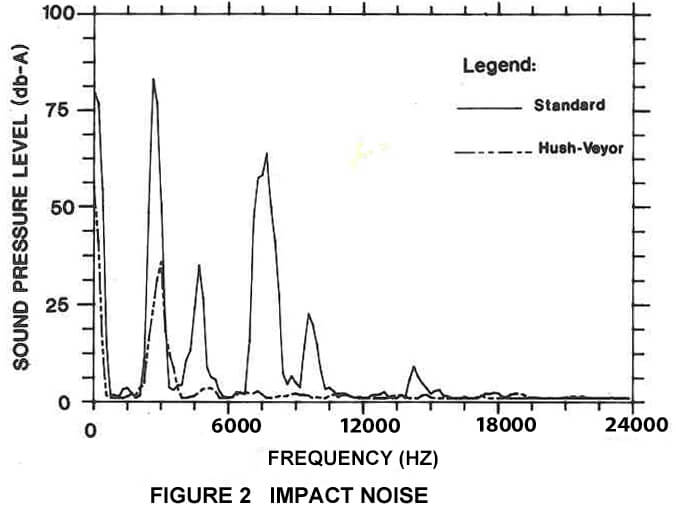

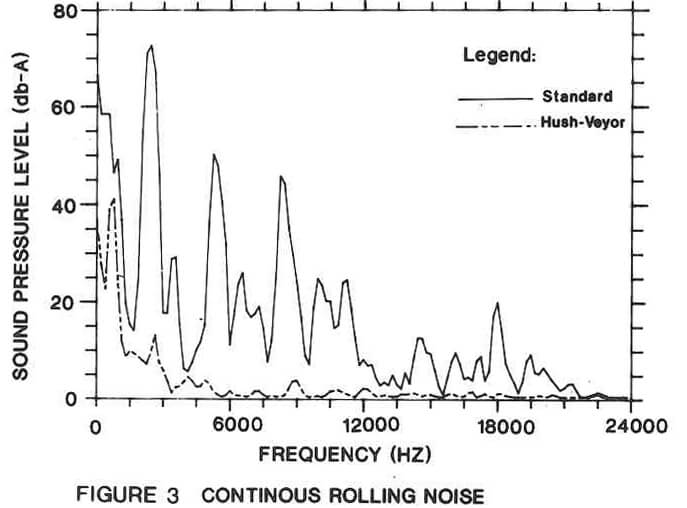

Hushveyor Technology

Workplace noise isn’t just an annoyance — it’s a safety and productivity concern. That’s why Webb-Stiles developed Hushveyor, a roller innovation that reduces noise without requiring changes to your system layout or operation.

How It Works

Hushveyor rollers are engineered with internal damping features that absorb impact and vibration during both start-up and continuous rolling. Unlike other noise-reducing options, they don’t require any changes to your layout or drive configuration.

Test Results

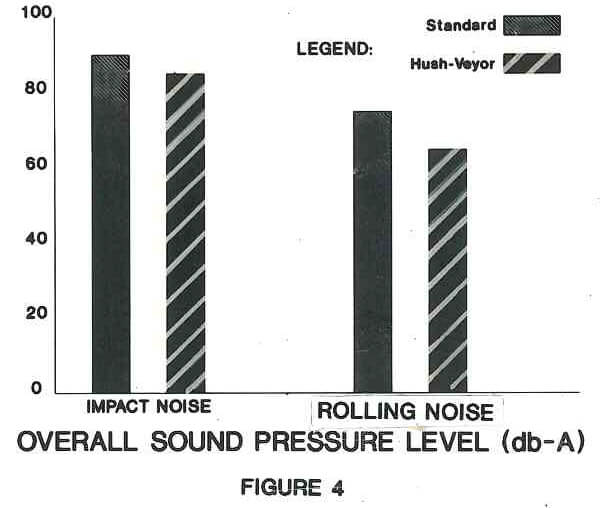

Independent acoustic testing showed significant reductions in overall sound pressure:

-

Up to 5 dB quieter during impact events

-

Up to 10 dB quieter during continuous rolling

-

High-frequency resonances (like 4500–9000 Hz) virtually eliminated

Altogether, that translates to a 2–3x reduction in perceived noise to the human ear. Additionally, results show noise pressure levels drop by up to 10 dB across both impact and rolling conditions.

Key Benefits

-

Helps meet OSHA noise level standards

-

Improves operator comfort and safety

-

No impact on conveyor speed, torque, or performance

-

Available on multiple roller types and sizes

In-House Manufacturing

At Webb-Stiles, every conveyor roller is built in our own facility using a custom-engineered automated roll machine. Because of this we are able to maintain complete control over quality, lead times, and custom capabilities—without relying on outside suppliers.

Precision at Every Step

From tubing prep and cutting to reaming, swaging, and final assembly, every stage is performed by our skilled team. In each phase, shafts, bearings, and custom features are installed in-house, with rigorous checks at each step.

Flexible for Any System

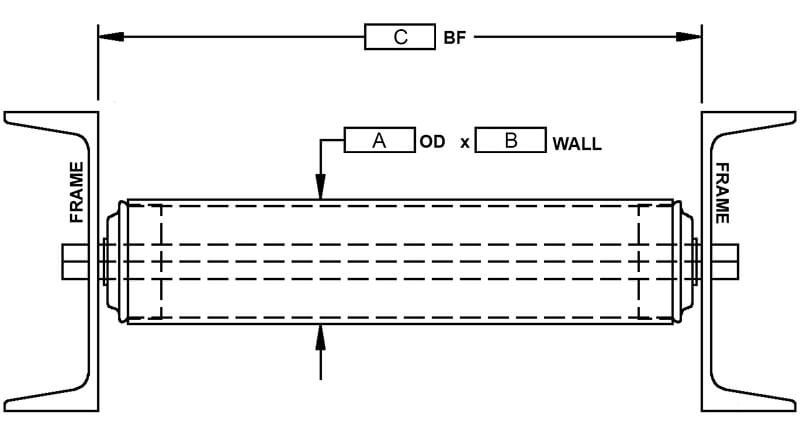

Whether you’re ordering 10 standard rollers or 1,000 custom builds, our process is designed for fast turnarounds and consistent output. As a result, we produce all standard roller sizes and can fabricate up to:

-

96” BF for swaged rollers

-

104” BF for reamed rollers

-

A full range of shaft styles, bearings, and sprocket configurations

Standard Conveyor Roller Sizes

Whether you’re designing a new system or replacing existing rollers, our standard sizes offer a reliable starting point for most applications. These rollers are produced in-house for consistent performance, fast turnaround, and seamless integration with a wide range of conveyor layouts.

Need a custom size? We can engineer it. Nevertheless, these standard sizes are available for fast delivery.

How To Order Conveyor Rollers

Webb-Stiles rollers are available as part of complete conveyor systems or as individual units—whether you’re an OEM building your own line or need replacements for existing equipment. To help you get started, here’s what we’ll need based on your situation:

Included in a New System

If you’re purchasing a complete conveyor system from Webb-Stiles, we’ll select the correct rollers during the engineering process.

What We Determine:

-

Roller type based on layout (gravity, lineshaft, CDLR, etc.)

-

Load weight, spacing, and material requirements

-

Shaft style and bearing fit

-

Drive needs (sprockets, grooves, friction surface)

As a result, no additional action is needed—we’ll spec everything in-house and include it in your project proposal.

Stand-Alone Rollers (OEM, Retrofit, or Replacement)

If you’re ordering rollers outside of a full Webb-Stiles system—whether for your own build or to replace existing units—we’ll need a few specs to get started.

What to Provide (if known):

-

Between Frame (BF) dimension

-

Roller diameter & wall gauge

-

Shaft style (hex, round, keyed, etc.)

-

Bearing type (free-running, grease-packed, precision)

-

Drive features (sprockets, grooves, urethane sleeve)

-

Quantity and any special details

Don’t worry if you’re missing some of this information—send what you can, and we’ll help figure out the rest.

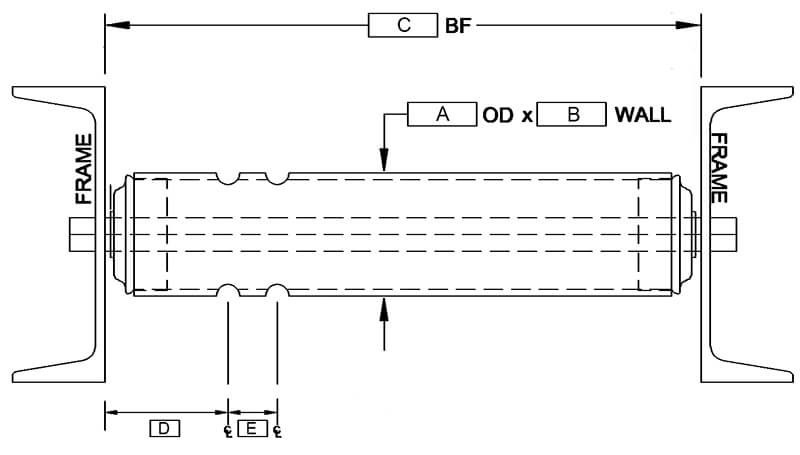

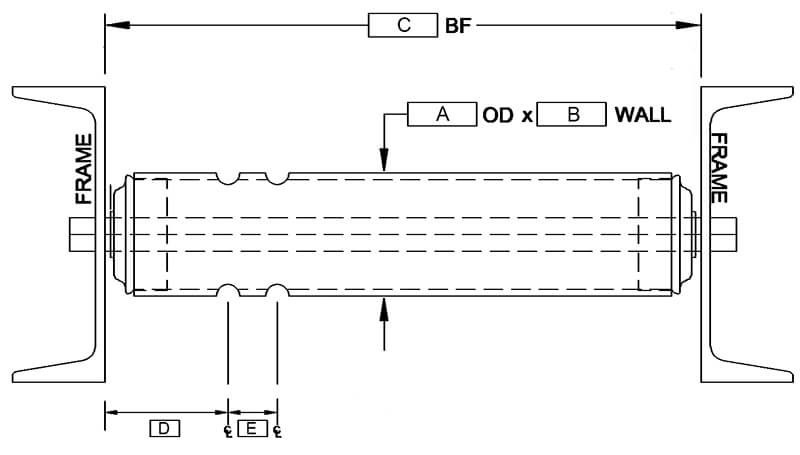

Roller Measurements and Required Specs

Gravity Roller

A. Outer (Roller) Diameter

B. Wall Thickness (Gauge)

C. Between Frame Width (BF)

Grooved (Lineshaft) Roller

A. Outer (Roller) Diameter

B. Wall Thickness (Gauge)

C. Between Frame Width (BF)

D. Groove Locations

E. Distance between Grooves

Sprocketed Roller

A. Outer (Roller) Diameter

B. Wall Thickness (Gauge)

C. Between Frame Width (BF)

D. Sprocket Locations

E. Distance between Sprockets

1. Download the Roller Order Guide

Includes part number format, shaft/bearing options, and configuration tips. Additionally, if you want a step by step reference, refer to pages 16 – 18 of the brochure.

2. Complete the Roller Quotation Request Form

Need help? Send us a message and we’ll walk through it together

Still Have Questions?

Our team knows roller specs inside and out. If you’re unsure about what to submit, just send what you do know — we’ll help you figure out the rest.