Chain, Trolleys, & Attachments Overhead Conveyor Components

Webb-Stiles offers a full line of overhead conveyor components, including drop forged rivetless chain, forged ball bearing trolleys, and a wide range of attachments for 3”, 4”, and 6” systems. Each component is built for strength, durability, and consistent performance, whether you’re outfitting a new conveyor or replacing parts in an existing system. With precision engineering and proven designs, these components deliver long service life and dependable operation in demanding environments.

Drop Forged Rivetless Chain

Overview

Simple Yet Strong Chain Design

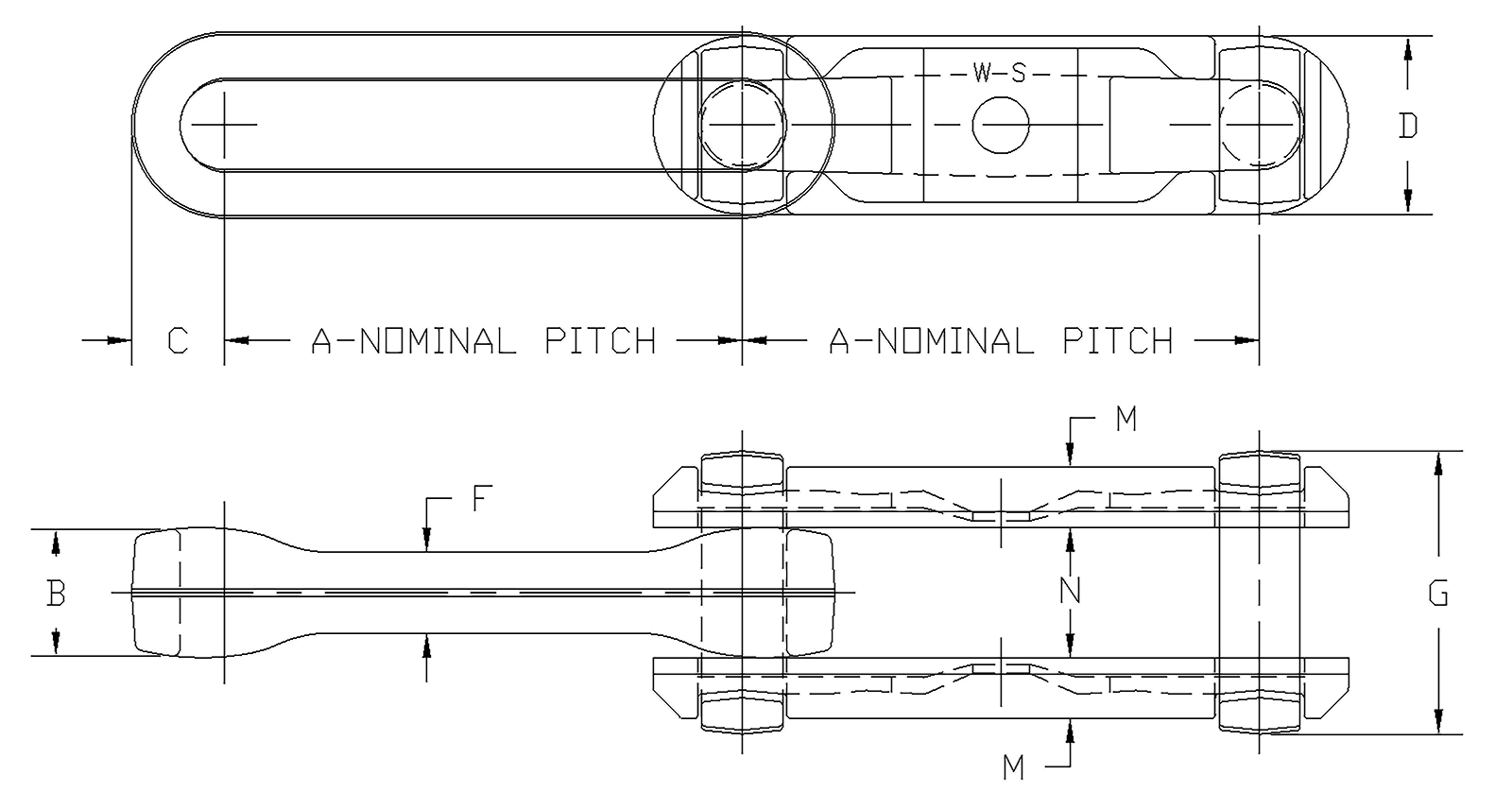

As part of our complete line of Overhead Conveyor Components, Webb-Stiles’ improved “X-type” rivetless overhead conveyor chain is drop-forged from high-carbon steel. Each link is made from just three parts: the connecting pin, side links, and center link. This simple and strong design delivers high durability with relatively low weight, making it ideal for demanding conveyor applications.

Built for Harsh Environments

Each chain component is heat-treated for exceptional strength, wear resistance, and the ability to withstand shock, abrasion, and corrosion. As a result, this chain performs smoothly through both horizontal and vertical curves—even in extreme operating conditions.

Easy Installation and Maintenance

No special tools or equipment are needed for assembly or disassembly. Links or chain sections can be replaced quickly, and the design ensures a secure, reliable connection during operation.

Specialized Chain Options Available

In challenging environments or wash-down areas where oiling is impractical, special alloy chain options are available. Contact Webb-Stiles for availability and technical support.

Strength, dimensions, and weights

| Chain Number | Nominal Pitch | Actual Pitch | Average Ultimate Strength (Pounds) | Recommended Chain Pull (Pounds) | Maximum Chain Pull (Pounds) | Weight (Pounds) | |||

|---|---|---|---|---|---|---|---|---|---|

| Per Foot | Center Link | Side Bar | Pin | ||||||

| X-348 | 3" | 3.031" | 24,000 | 1,500 | 2,500 | 2.14 | .37 | .22 | .13 |

| X-458 | 4" | 4.031" | 48,000 | 3,000 | 4,000 | 3.14 | .81 | .39 | .25 |

| X-678 | 6" | 6.031" | 85,000 | 5,000 | 6,000 | 6.5 | 2.27 | 1.39 | .67 |

Note: When computing chain pull, trolley spacing, vertical bend radius, conveyor speed and operating conditions should be taken into account.

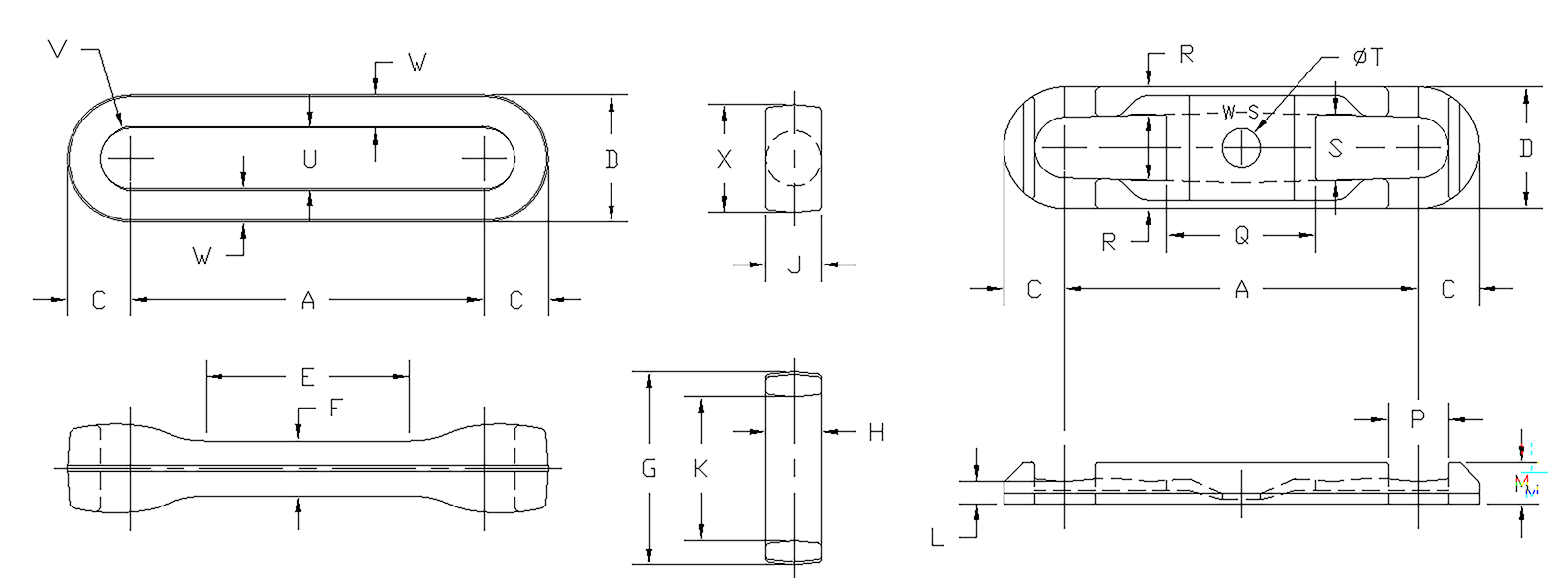

Dimensional Data

| Chain | A | B | C | D | E | F | G | H | J | K | L | M | N | P | Q | R | S | T | U | V | W | X |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| X-348 | 3 | 34 | 916 | 1116 | 11316 | 12 | 12332 | 12 | 12 | 1932 | 14 | 1332 | 2532 | 916 | 1116 | 1564 | 1932 | 38 | 916 | 14 | 14 | 1 |

| X-458 | 4 | 1 | 2332 | 138 | 2516 | 58 | 2316 | 58 | 58 | 158 | 932 | 1532 | 1116 | 716 | 134 | 916 | 34 | 716 | 1116 | 1132 | 132 | 1732 |

| X-678 | 6 | 1932 | 1116 | 2 | 312 | 1316 | 3132 | 78 | 2932 | 2732 | 716 | 1116 | 11332 | 3132 | 238 | 12 | 1 | 12 | 1 | 1532 | 12 | 178 |

all measurements are in inches if not otherwise specified

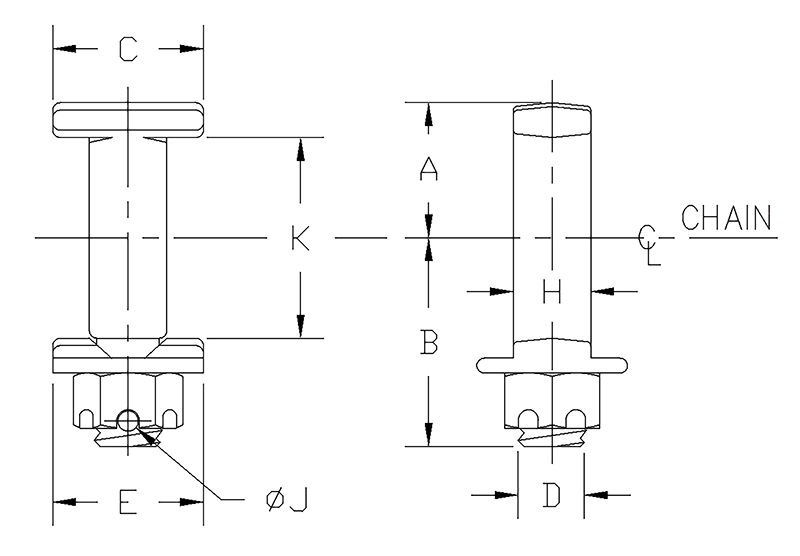

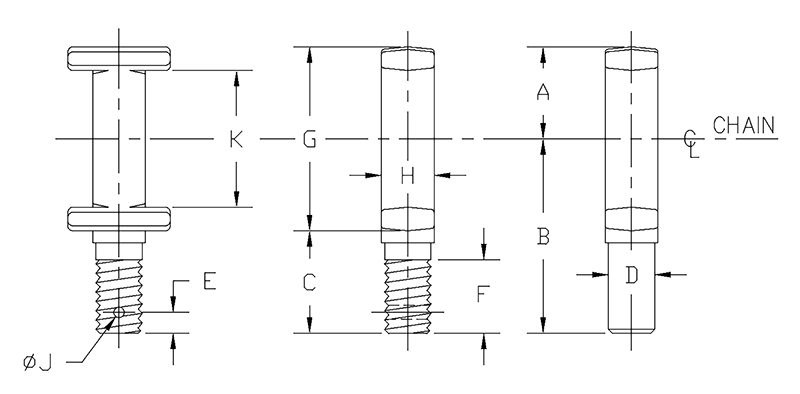

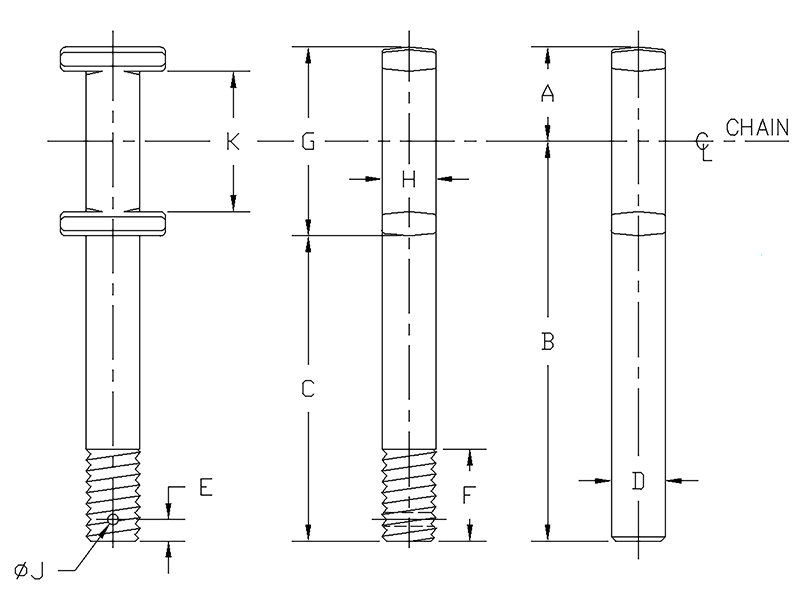

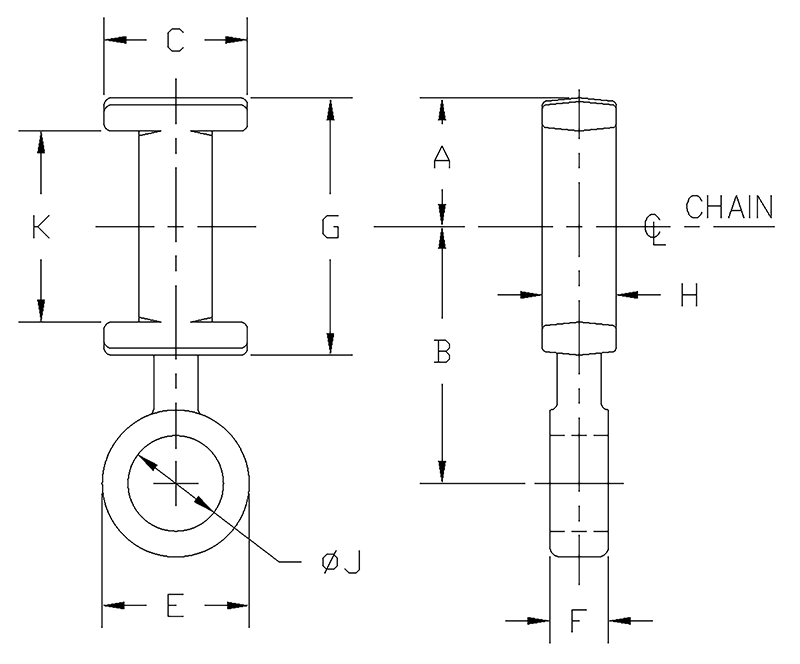

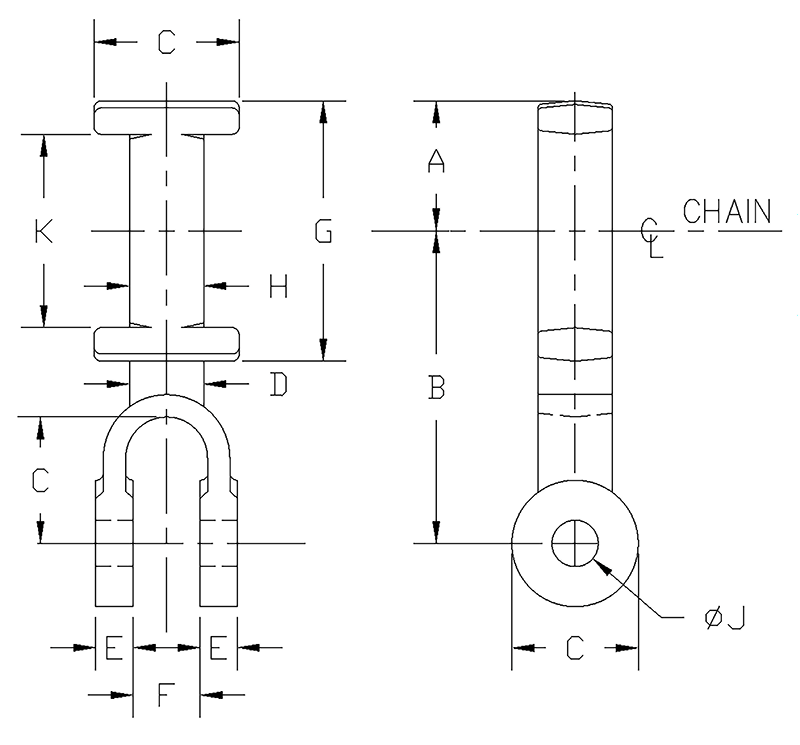

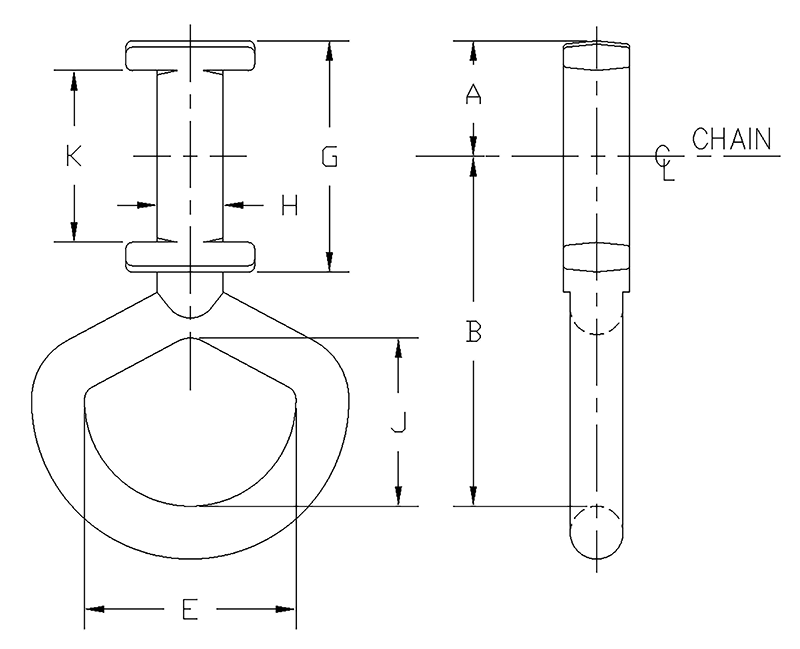

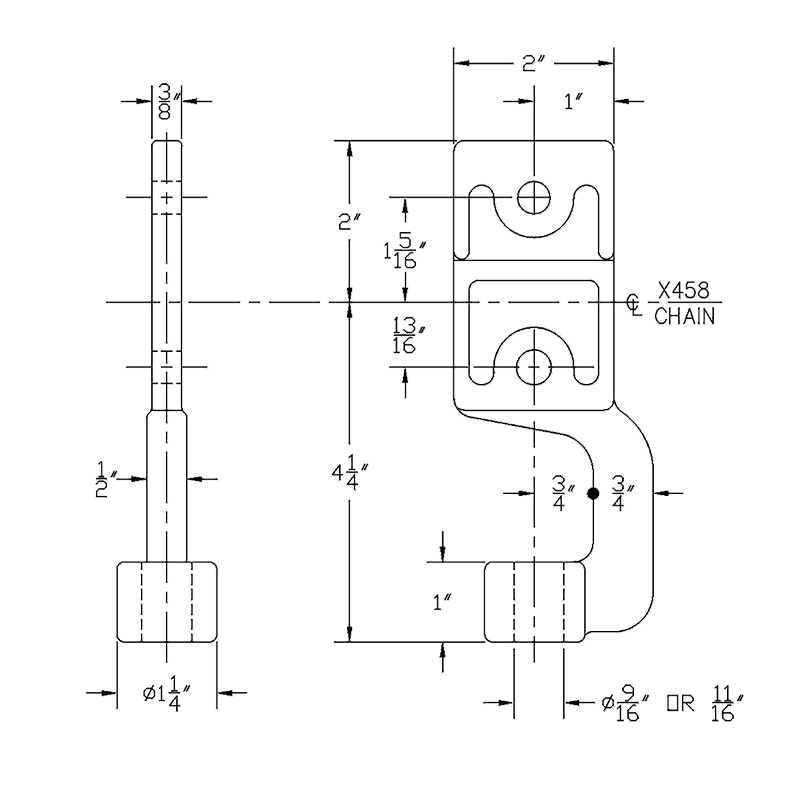

Chain Pins & Attachments

Overview

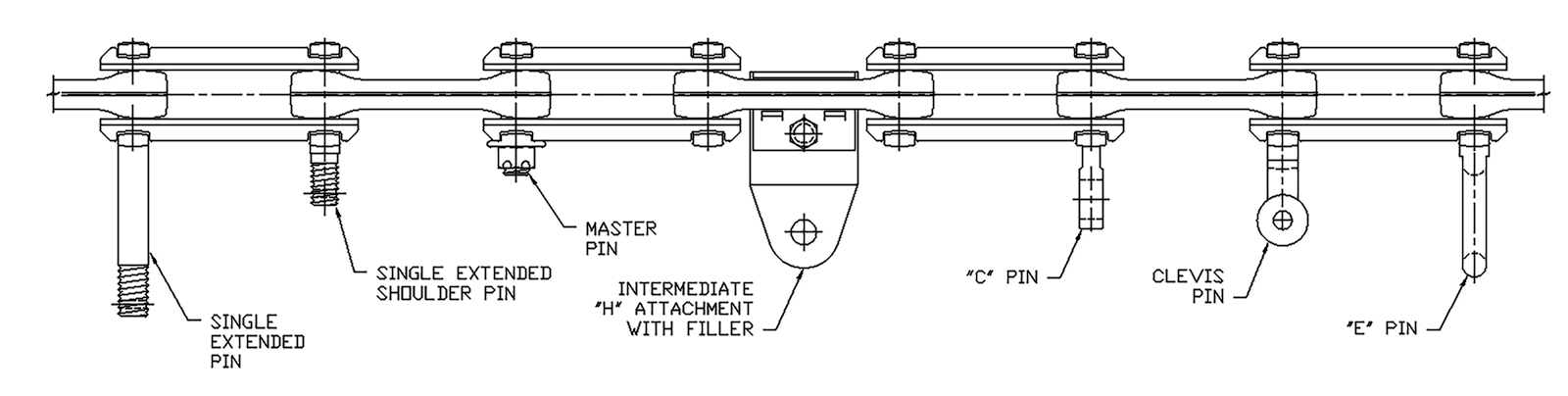

Chain attachments are commonly used in overhead conveyor systems to carry multiple light loads. Because these attachments hang between trolleys without direct track support, the load must be kept light to avoid excessive chain sag.

To meet different needs, a wide variety of attachment types is available. These attachments replace the standard rivetless chain pin and are offered for both X-348 and X-458 chains. The Master Pin is the only exception.

Each attachment is designed to match the dimensions of a standard chain pin. As a result, installers can easily substitute pins during maintenance or setup.

Note: The Master Pin is not intended to carry a load. Instead, its purpose is to connect chain ends in layouts with limited slack, making it easier to assemble and disassemble the conveyor when under tension.

Attachment Types and Dimensional Data Table

| Chain Attachment | Chain Number | A | B | C | D | E | F | G | H | J | K |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Master Pin | X-348 | 2732 | 1716 | 1 | 38 | 1 | --- | --- | 12 | 18 | 1932 |

| X-458 | 1332 | 11116 | 1132 | 12 | 114 | --- | --- | 58 | 18 | 158 | |

| X-678 | 112 | 238 | 178 | 58 | 178 | --- | --- | 78 | 532 | 214 | |

| Single Extended Shoulder Pin | X-348 | 2732 | 11516 | 1116 | 12 | 14 | 78 | 12332 | 12 | 18 | 1932 |

| X-458 | 1332 | 2516 | 1732 | 12 | 14 | 78 | 2316 | 58 | 18 | 158 | |

| Extended Pin Long | X-458 | 1332 | 658 | 51732 | 58 | 14 | 112 | 2316 | 58 | 18 | 158 |

| "C" Pin | X-458 | 1332 | 218 | 1732 | --- | 114 | 12 | 2316 | 58 | 1316 | 158 |

| Clevis Pin | X-348 | 2732 | 212 | 1116 | 12 | 516 | 916 | 12332 | 12 | 2564 | 1932 |

| X-458 | 1332 | 4 | 1116 | 58 | 516 | 916 | 2316 | 58 | 2564 | 158 | |

| "E" Pin | X-458 | 1332 | 314 | 1732 | --- | 2 | 12 | 2316 | 58 | 158 | 158 |

| Intermediate "H" Attachment | X-348 | 34 | 318 | 78 | 134 | 18 | 916 | 58 | 1132 | 1732 | 158 |

| X-458 | 1 | 278 | 1316 | 214 | 316 | 1116 | 34 | 1332 | 1732 | 134 | |

| Intermediate "J" Attachment | X-458 | 1 | 414 | 1 | 1 | 34 | 34 | 916 | 1332 | 916 | 1116 |

all measurements are in inches if not otherwise specified

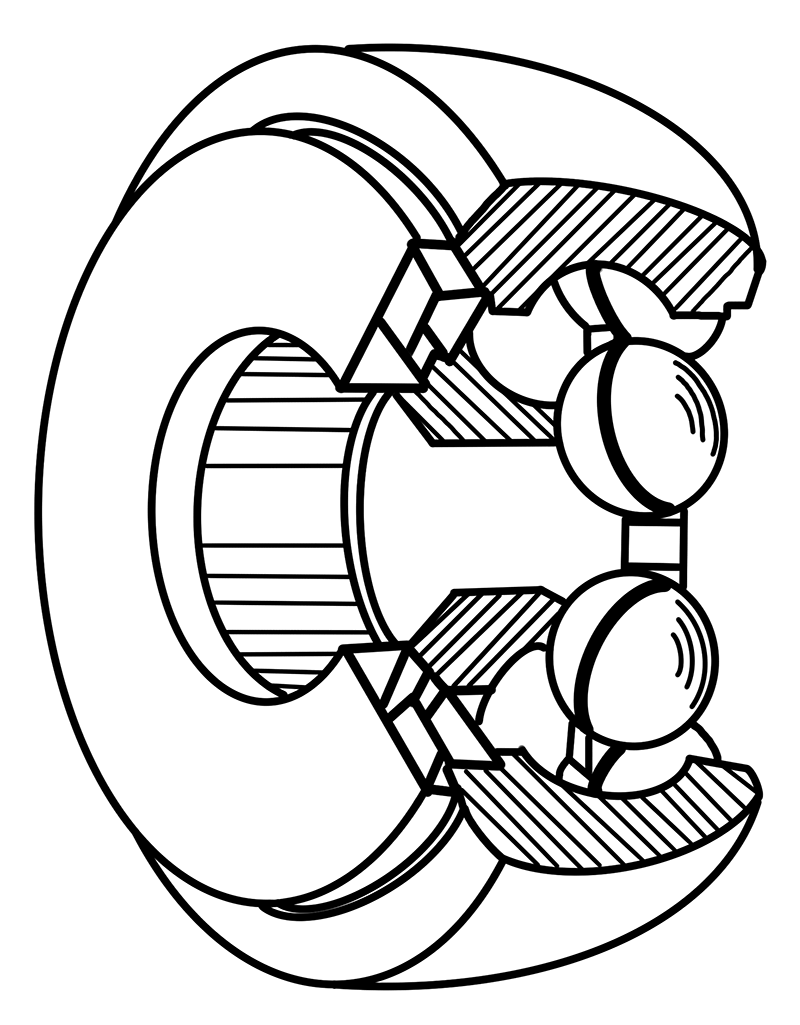

Forged Ball Bearing Trolley Assembly

Overview

Webb-Stiles Overhead Conveyor Trolley Assemblies are available for 3-inch, 4-inch, and 6-inch track sizes. These sizes provide reliable load-carrying performance for overhead conveyor systems.

Each standard assembly includes two conveyor wheels and a pair of precision-engineered trolley brackets. When combined with attachments, the trolleys lock securely into the center link of the rivetless chain. As a result, they offer long service life and dependable performance with minimal maintenance—even in demanding applications.

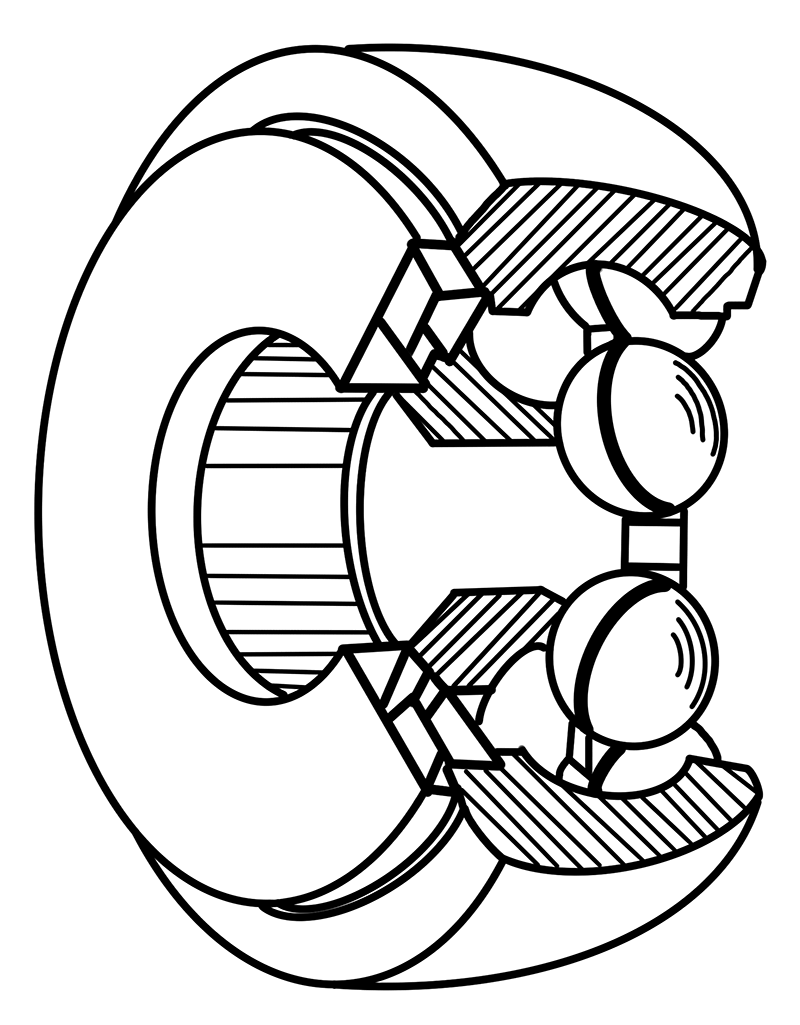

Trolley Wheels:

The flangeless design features an improved tread contour and is machined from high-quality solid steel stock. To maximize durability, the material is hardened for extended wear.

Additionally, the tread doubles as the outer ball race. This surface is precision ground to ensure smooth motion. The contoured shape also reduces friction, minimizes slippage, and helps prevent track flange damage during operation.

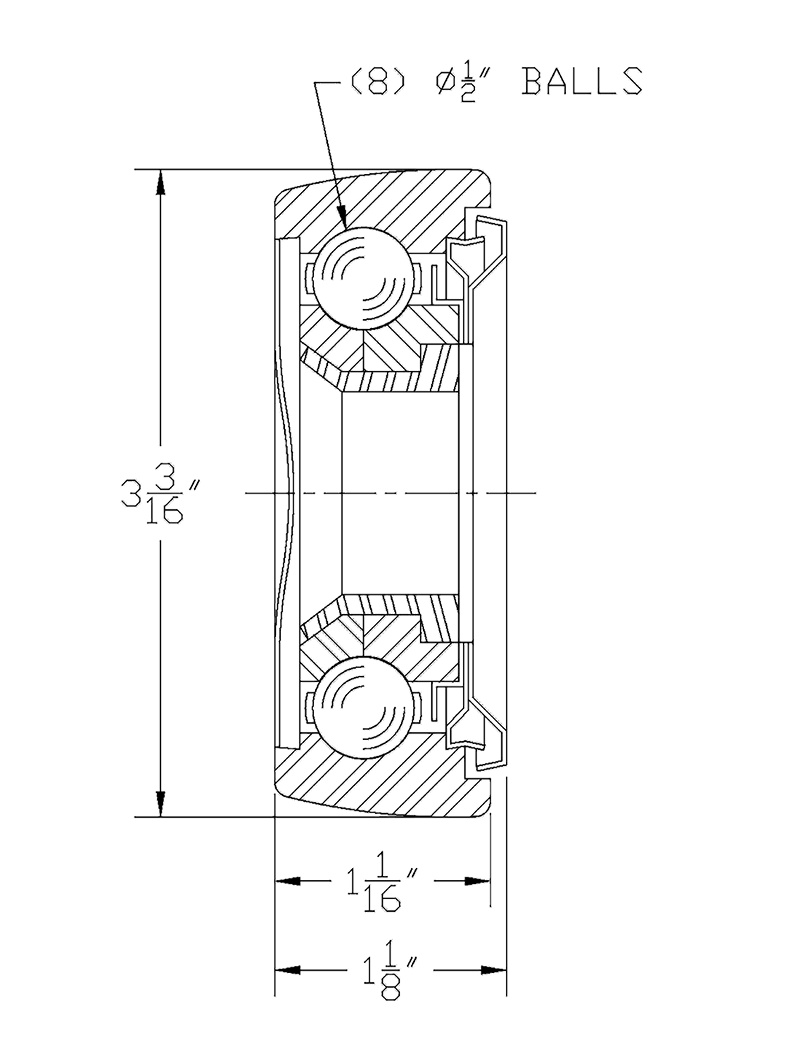

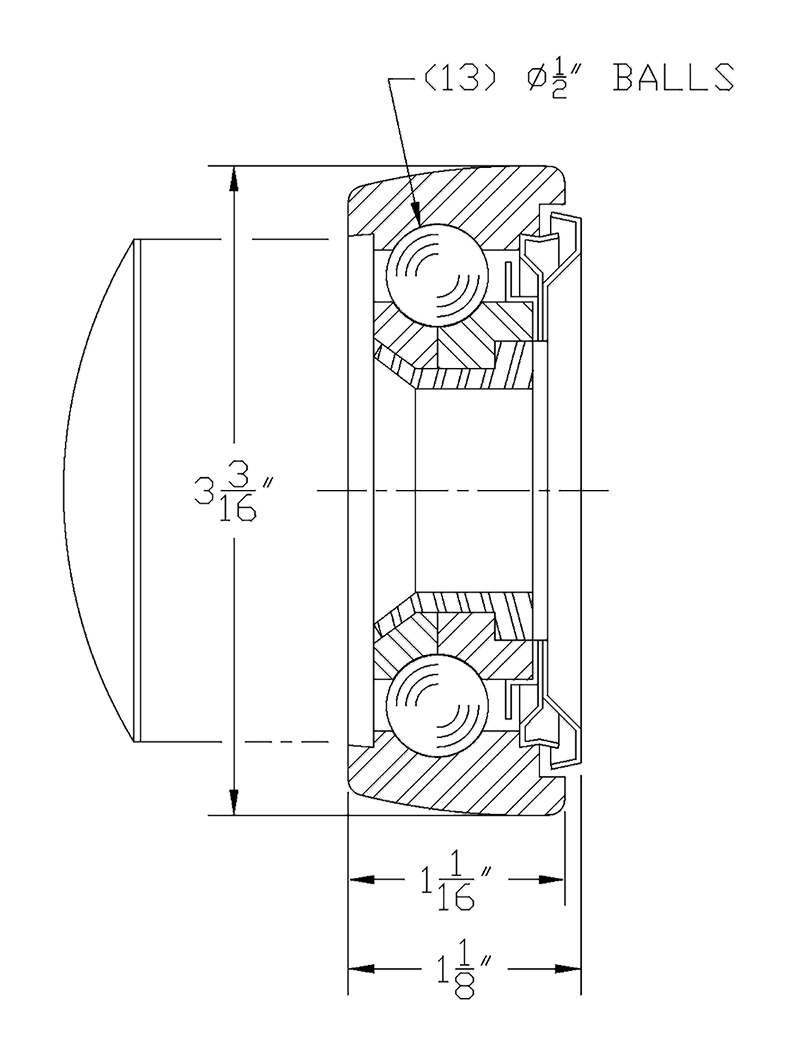

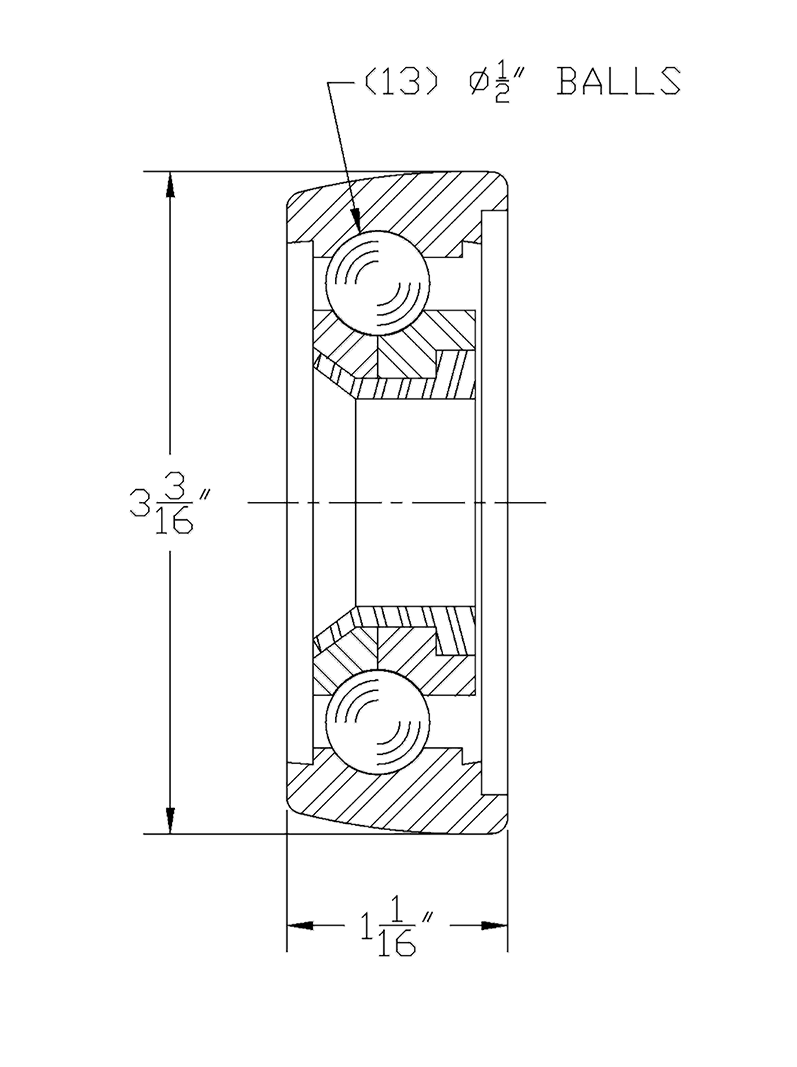

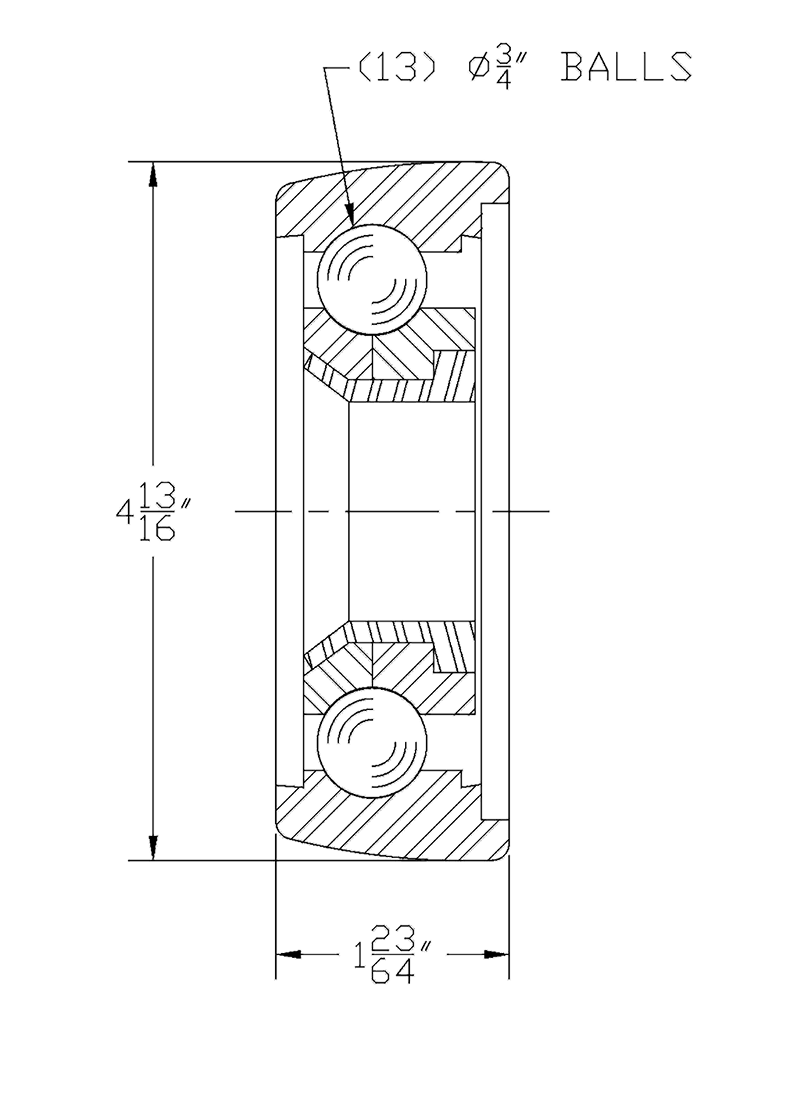

Bearings:

Trolley assemblies use a standard full-complement bearing with large-diameter, precision-ground balls. When needed for specialized applications, a two-piece retainer-style bearing can be substituted.

Inner Race:

The inner race is precision-machined and hardened to retain the bearing securely. It is swaged to the trolley bracket as part of the standard manufacturing process, ensuring long-term reliability without extra fasteners.

Trolley Bracket:

Trolley brackets are drop-forged from high carbon steel and feature double-ribbed cross sections for added strength. This design helps resist bending or spreading under heavy loads.

Wheel bearings are swaged into a collar on the bracket. In addition, a heavy, shrouded bracket head protects the grease fitting—eliminating the damage risks often seen with exposed press-in styles.

Trolley Assembly:

Each complete trolley includes two half trolleys and a compatible attachment. These components bolt securely through the center link of the rivetless chain.

For specific chain compatibility and load ratings, refer to the Trolley Section.

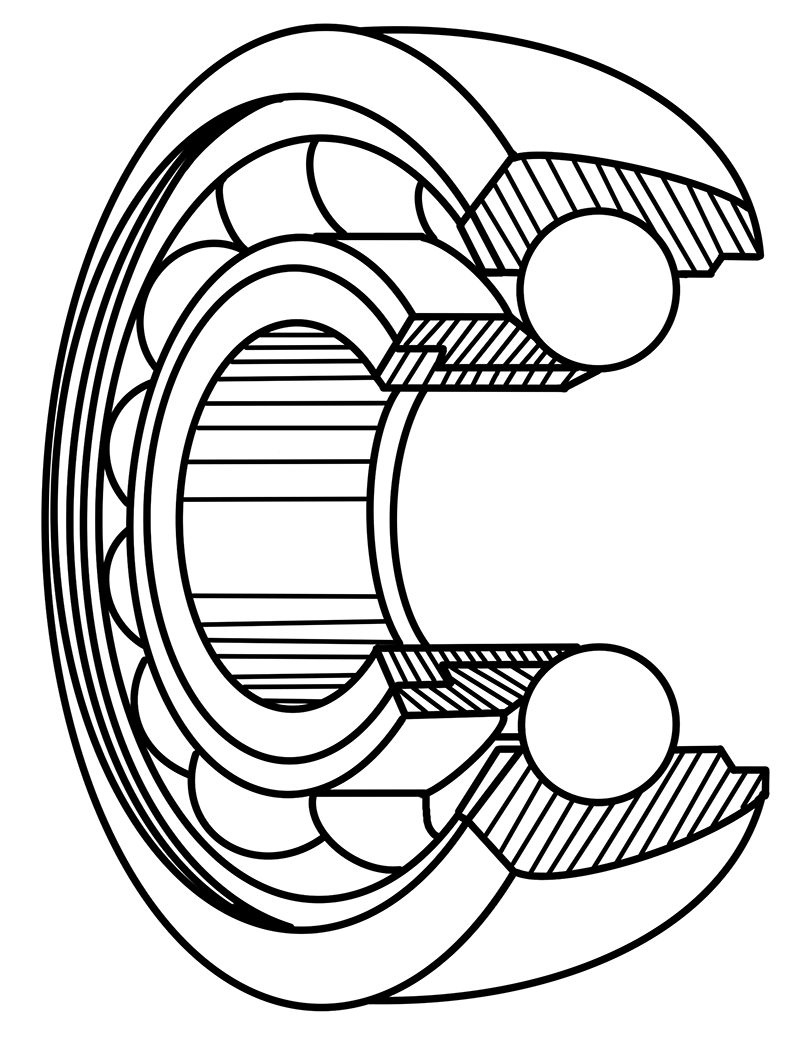

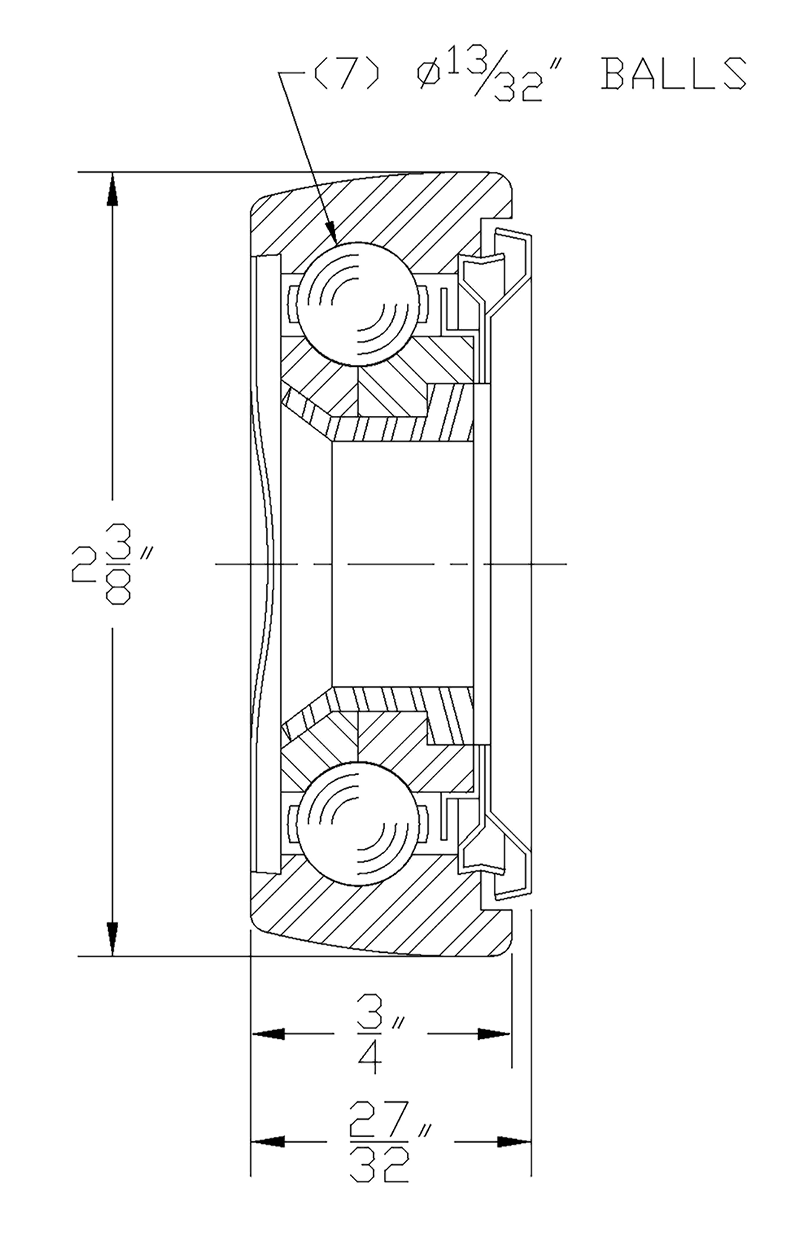

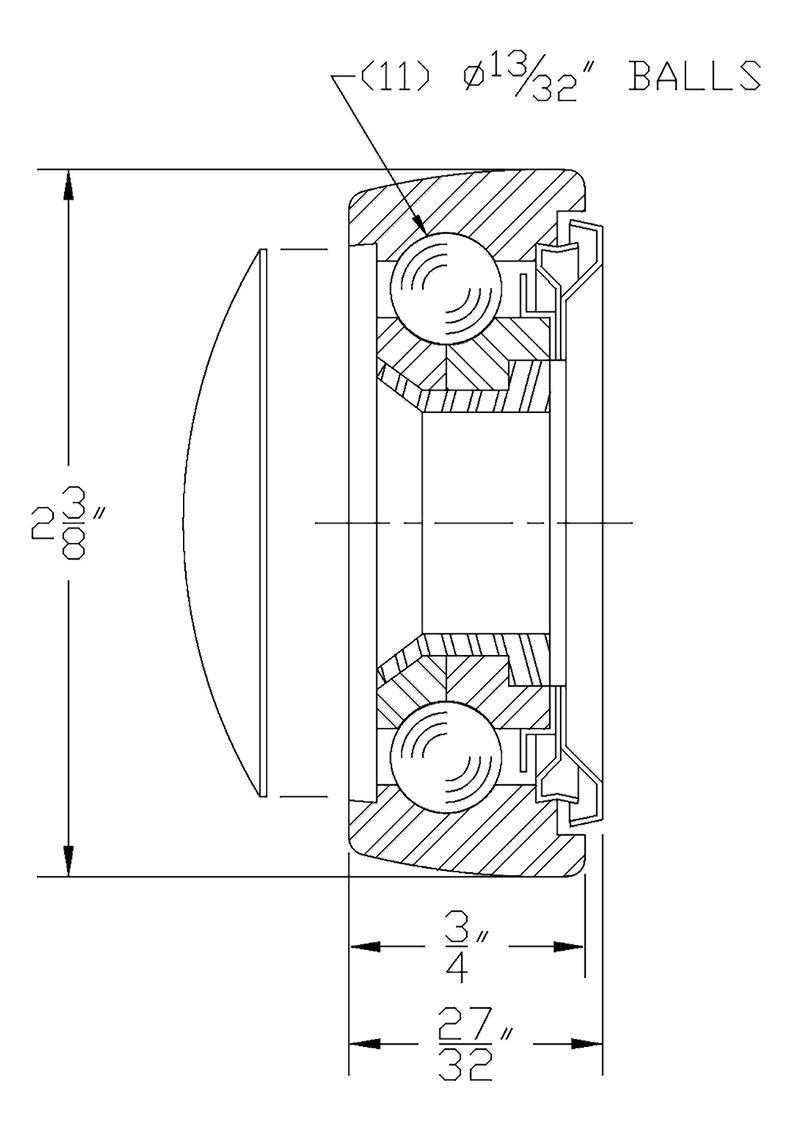

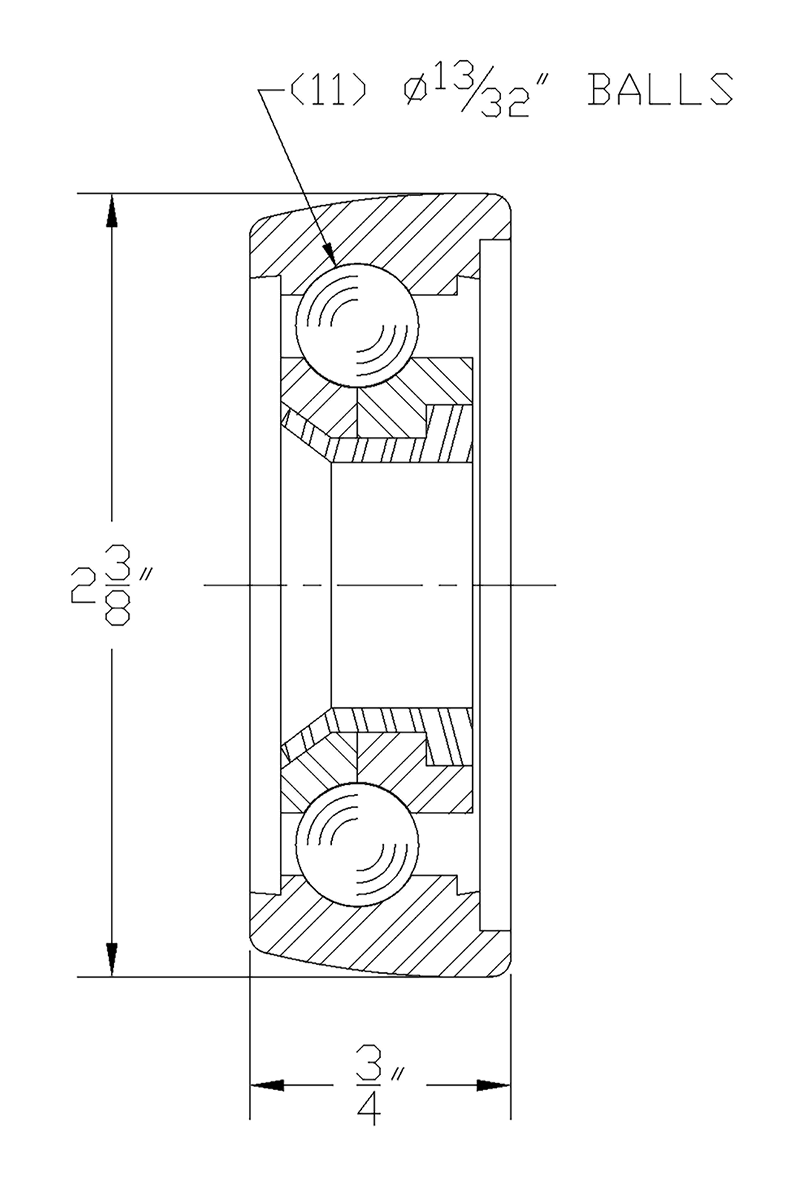

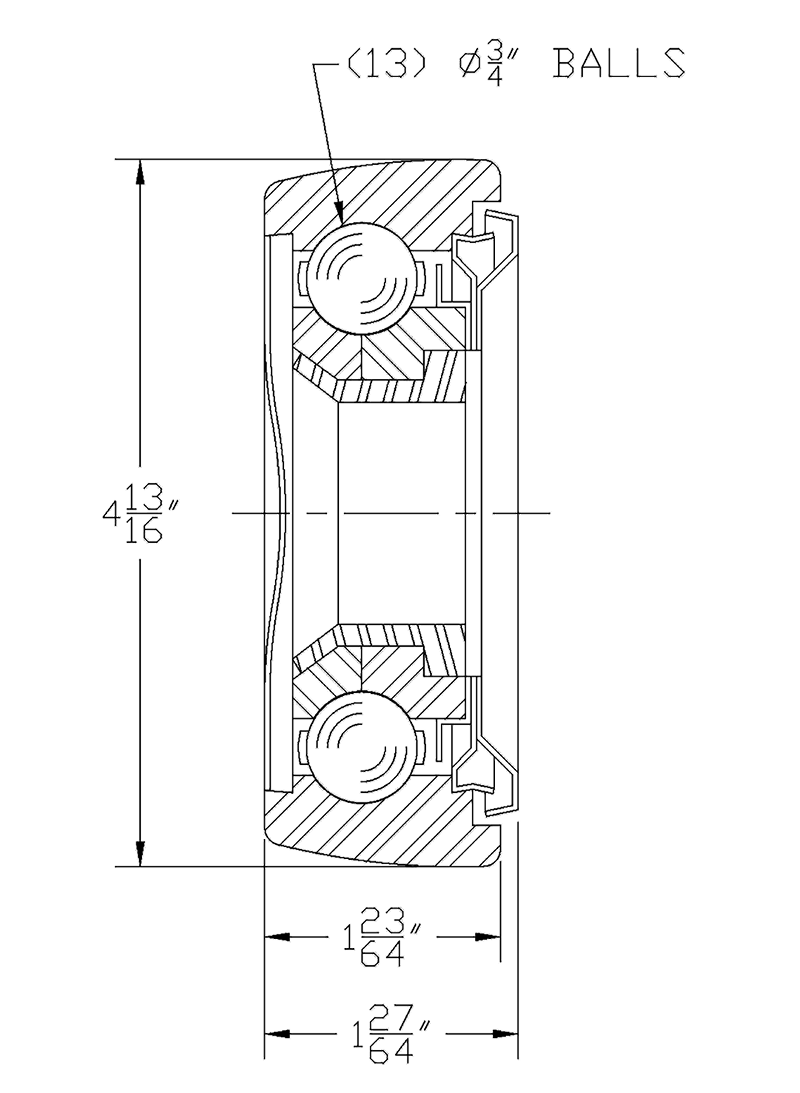

Trolley Wheels

Webb-Stiles conveyor trolley wheels with ball bearings are engineered for durability, smooth performance, and long service life. Available in both Full Complement and Two-Piece Retainer styles, each bearing type is designed for specific conveyor demands.

Our standard configuration features the inner bearing race precision-swaged to the trolley bracket. This provides superior strength and long-term reliability.

For unique system needs, custom seal and bearing combinations are also available.

Retainer Type, Sealed (optional)

This bearing features a two-piece construction with precision-ground steel balls and a durable metal retainer.

Triple labyrinth metal seals create a self-purging, triple grease barrier for long service life. A side-arm grease fitting allows easy maintenance. Additionally, optional high-temperature grease supports continuous use above 200°F (93°C).

Full Ball Complement, Sealed (standard)

This one-piece sealed bearing uses large, precision-ground balls without a retainer. The result is maximum load capacity and smooth operation under heavy-duty conditions.

Triple labyrinth seals and a side-arm grease fitting simplify maintenance. For elevated temperatures, an optional heat-resistant grease is available for continuous use above 200°F (93°C).

Open Type, Full Ball Complement

The open design is best suited for clean or controlled environments, especially systems with automatic spray-type lubricators.

It features precision-ground steel balls and no front or rear seals, allowing maximum lubrication flow. While it provides less protection from dust or debris, it ensures smooth, low-friction performance with minimal maintenance.

Front Seal Only, Full Ball Compliment

This version includes a front seal but leaves the rear open for spray lubrication systems. It’s ideal for I-beam tracks where targeted lubrication is used.

By using a front seal only, this design reduces overspray, improves efficiency, and minimizes lubrication waste—especially in environments where control and cleanliness matter.

Rear Seal Only, Full Ball Complement

The rear-seal-only full complement bearing is designed for overhead conveyor trolley wheels using front-side spray lubrication. Because the front of the wheel is exposed, grease can be applied directly, while the rear seal helps prevent overspray from reaching the I-beam track.

Built with precision-ground steel balls, this design ensures smooth operation, reduces contamination risk, and supports consistent lubrication control in industrial environments.

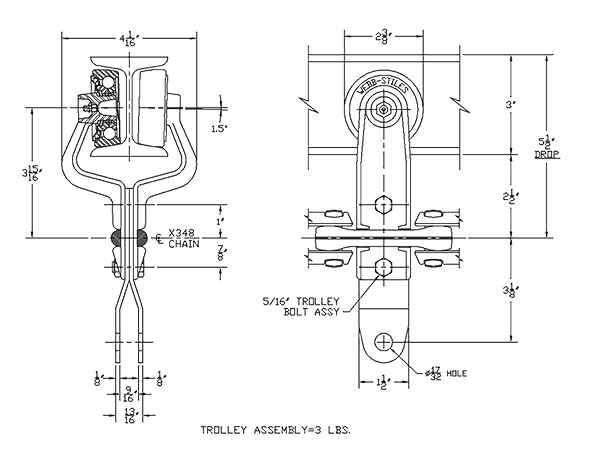

3 Inch Forged Ball Bearing Trolley Assembly

Load Capacity & Applications

The 3-inch overhead conveyor trolley system is engineered for light- to medium-duty applications, offering dependable load transport for manufacturing, assembly, and material handling environments. Typical load capacity ranges from 180 to 220 lbs per trolley, depending on the conveyor speed. While these trolleys can support heavier loads, staying within the recommended range ensures smooth performance, reduces wear on the system, and minimizes maintenance. For slower-speed systems without vertical curves, loads up to 300 lbs per trolley may be accommodated.

Track & Chain Compatibility

This system is designed for X-348 rivetless conveyor chain, with recommended spacing at 6-inch centers or in multiples up to 30 inches. Spacing beyond 30 inches is not advised, as it can lead to chain sag and negatively affect traction wheels, roller turns, and vertical curve performance. For best results, chain spacing should align with both load ratings and system geometry.

Construction & Attachments

Each forged trolley assembly is built around the X-348 rivetless chain, chosen for its strength and long-term durability. Brackets and attachments bolt directly to the chain’s center link, forming a secure and wear-resistant connection. Heavy-duty side pads ensure a tight chain fit, while a shrouded bracket head helps protect the grease fitting from impact.

The standard trolley wheel provided is the Full Complement – Sealed type, engineered for long service life with minimal maintenance. However, other wheel styles are also available to match specific operational needs. The standard attachment is the “H” (Clevis) style, with optional Pendant and Dummy attachments available for more flexible load-handling configurations.

3″ Trolley Wheels

Retainer Type – Sealed

Full Complement – Sealed

Full Complement – Open

| Type | Best For | Key Features | Heat Rating |

|---|---|---|---|

| Retainer Type – Sealed | General use | Two-piece ball bearing, steel retainer, triple labyrinth seals, side-arm grease fitting, optional high-temp grease | Up to 325°F |

| Full Complement – Sealed | Dirty environments, delivery conveyors | One-piece bearing, large precision-ground balls, triple labyrinth seals, side-arm grease fitting, optional high-temp grease | Up to 500°F |

| Full Complement – Open | Corrosive or high-temp applications | No seals/plugs, optional front/rear seals, requires auto flushing with light oil | Up to 500°F |

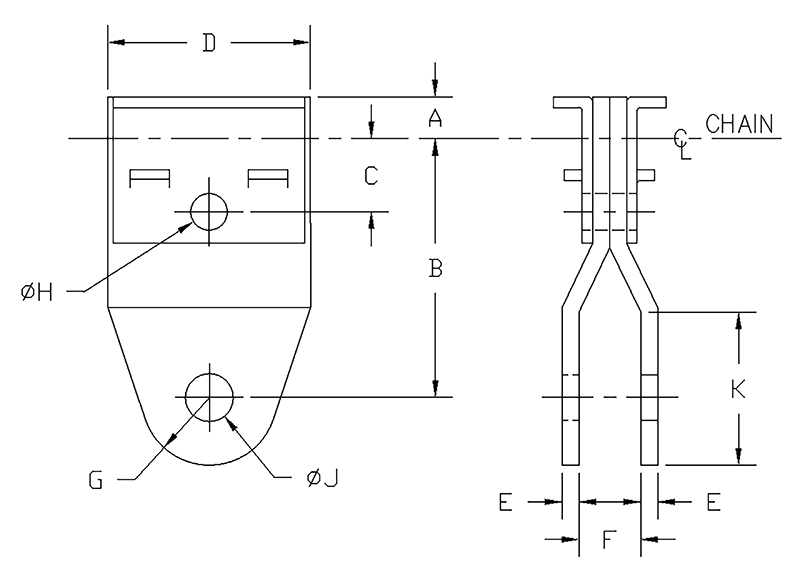

3″ Trolley Attachments

| Attachment | Use Case | Notes |

|---|---|---|

| H | Standard clevis | Supplied with all assemblies unless specified; for hooks and fittings; pins sold separately |

| C | Pendant clevis for light loads | Fits hook or carrier; accommodates bent rod hooks |

| D | Dummy for spacing | Used with intermediate trolleys when spacing exceeds 30″ |

| Trolley & Load Bar | Heavy loads | Uses two trolleys with load bar, washers, nuts, “B” attachments |

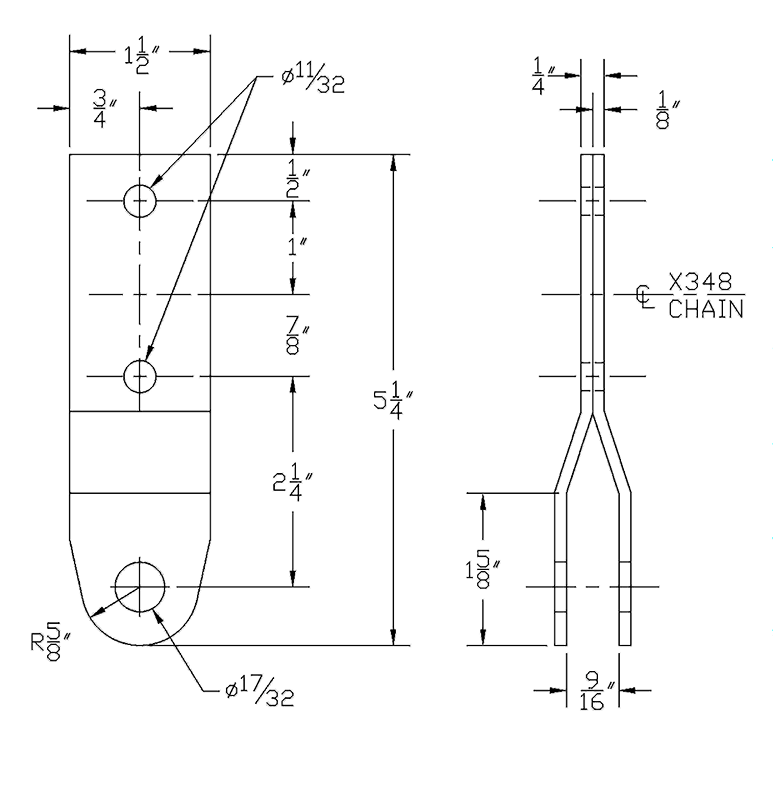

3″ H Attachment

3″ C Attachment

3″ D Attachment

3″ Trolley and Load Bar Assembly

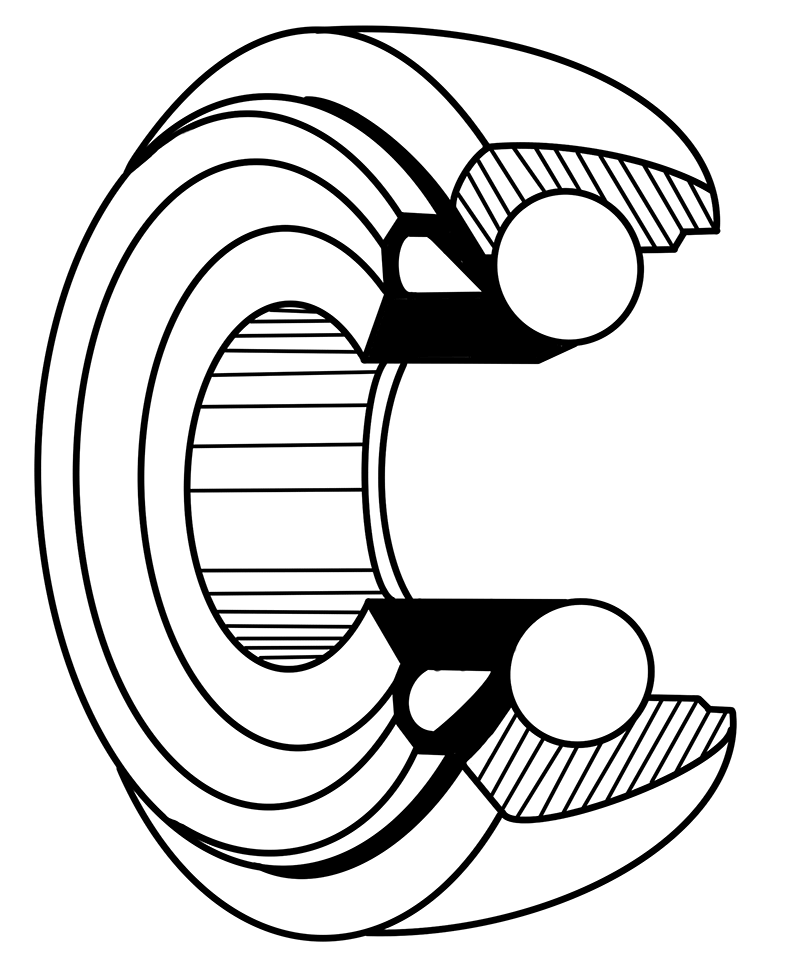

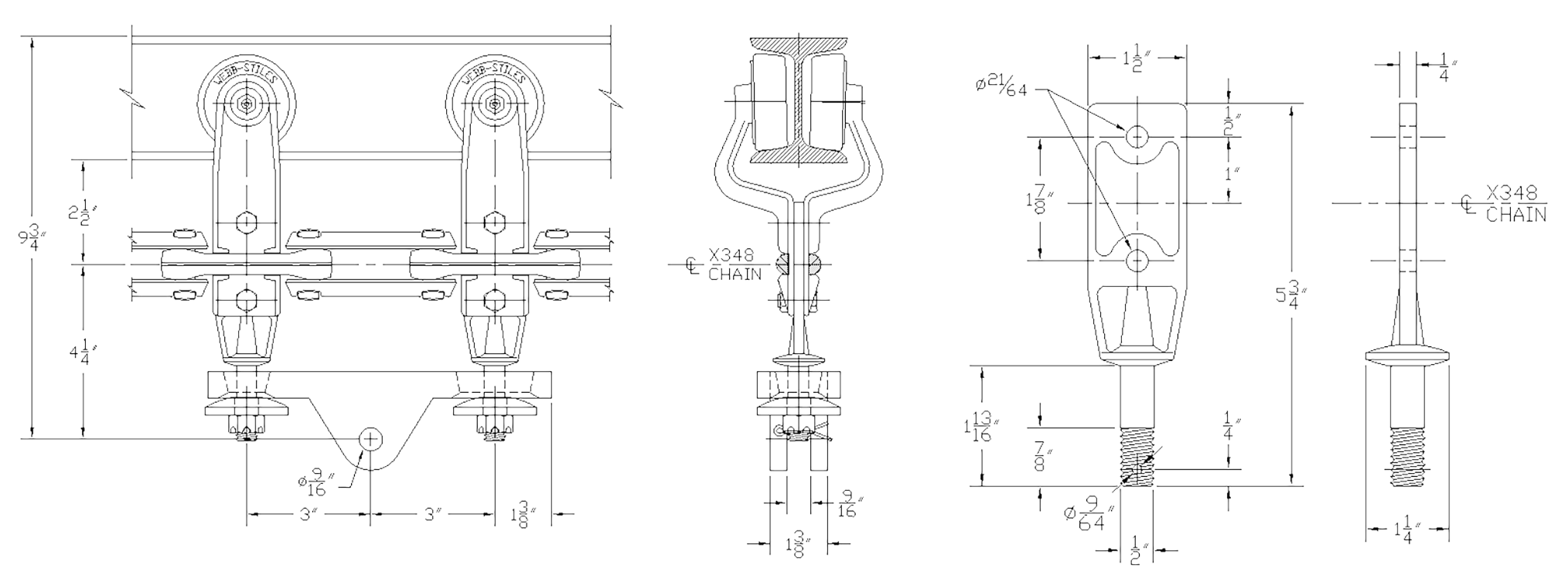

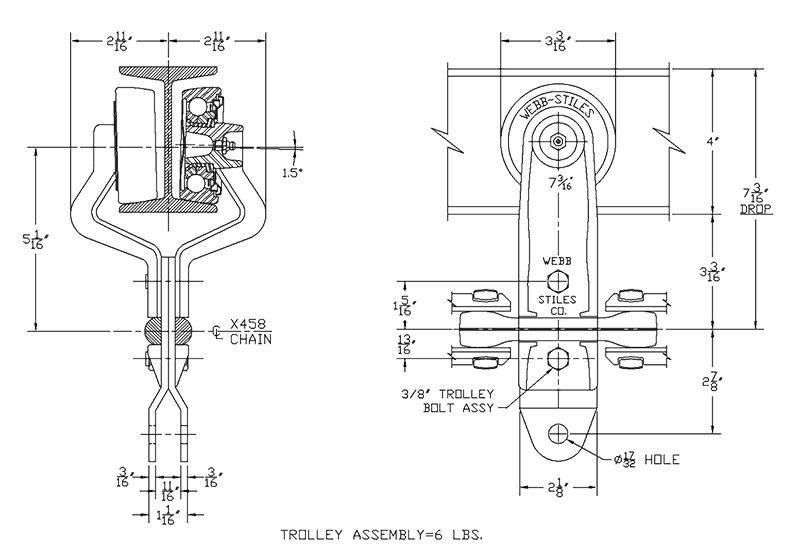

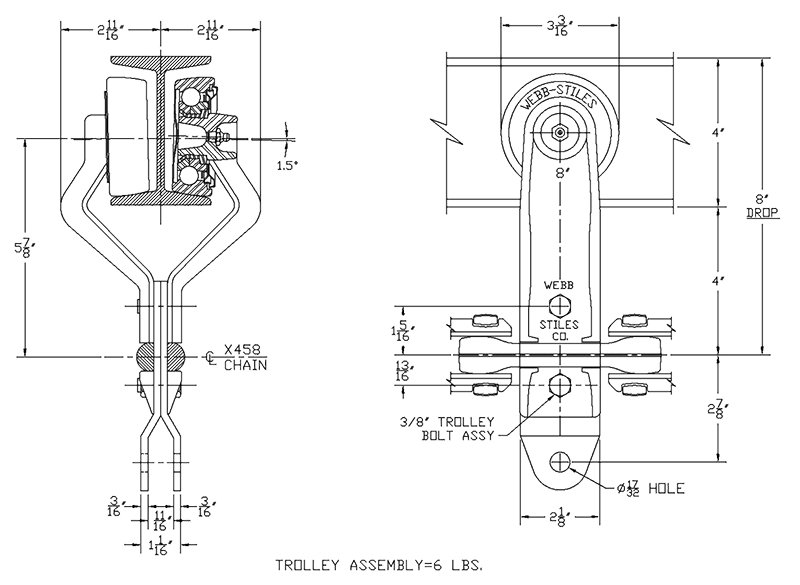

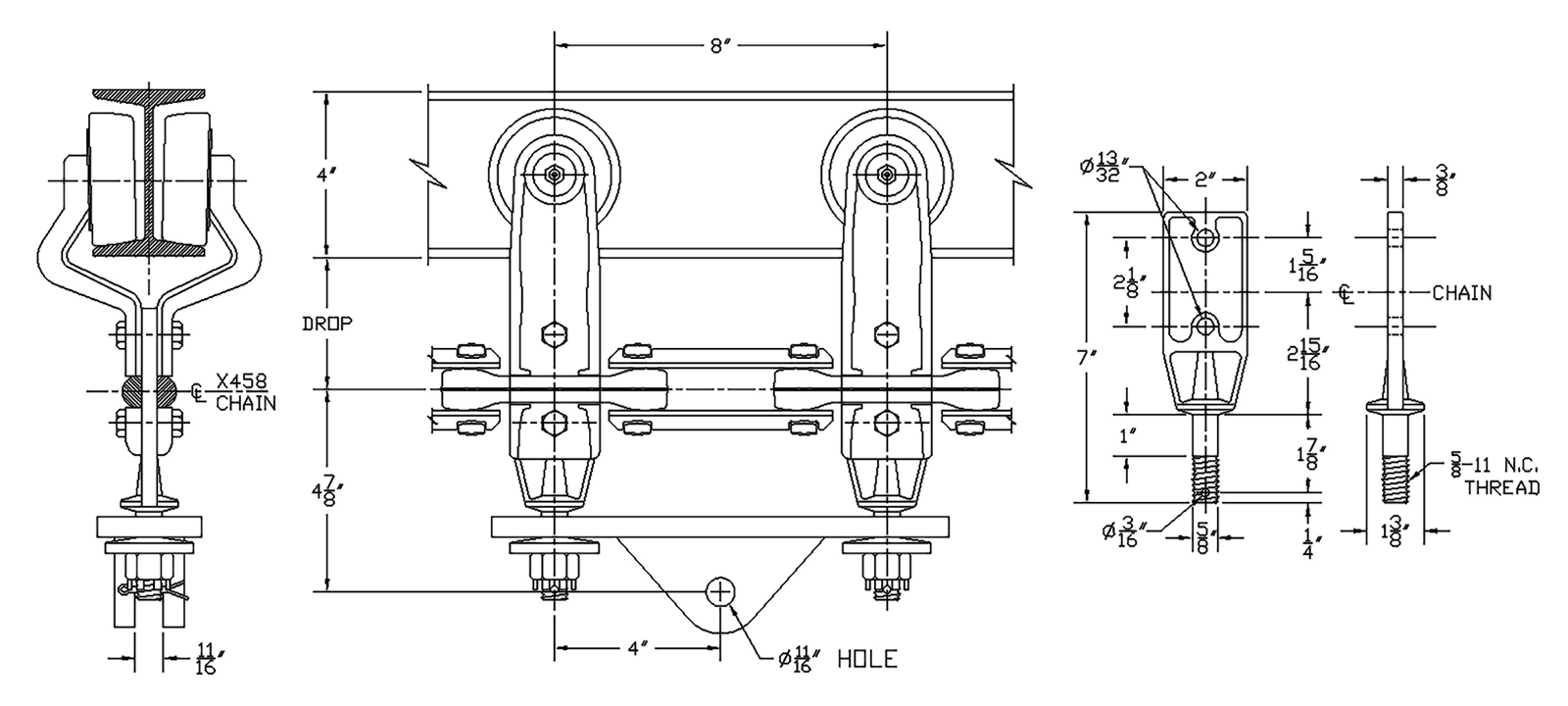

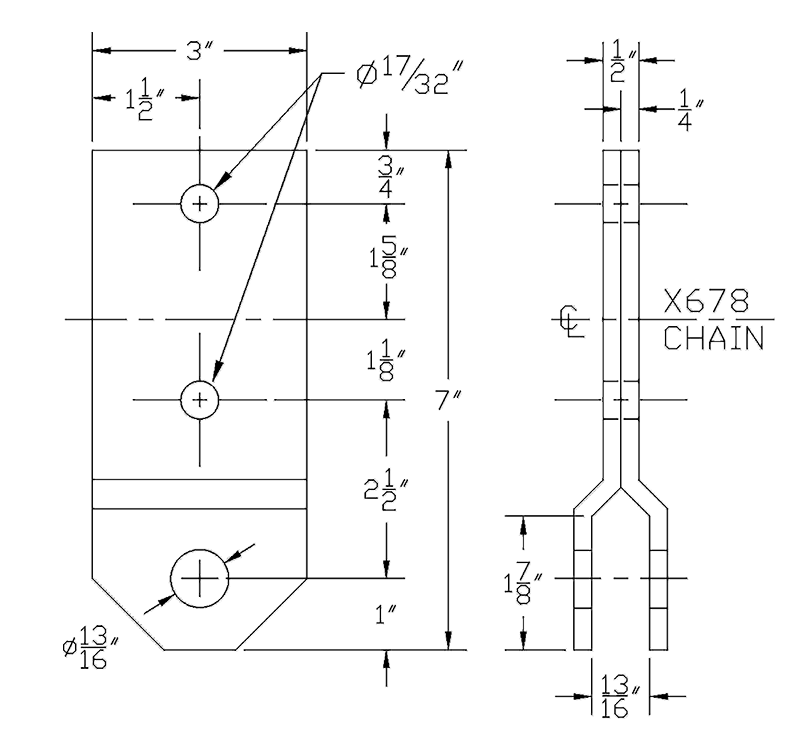

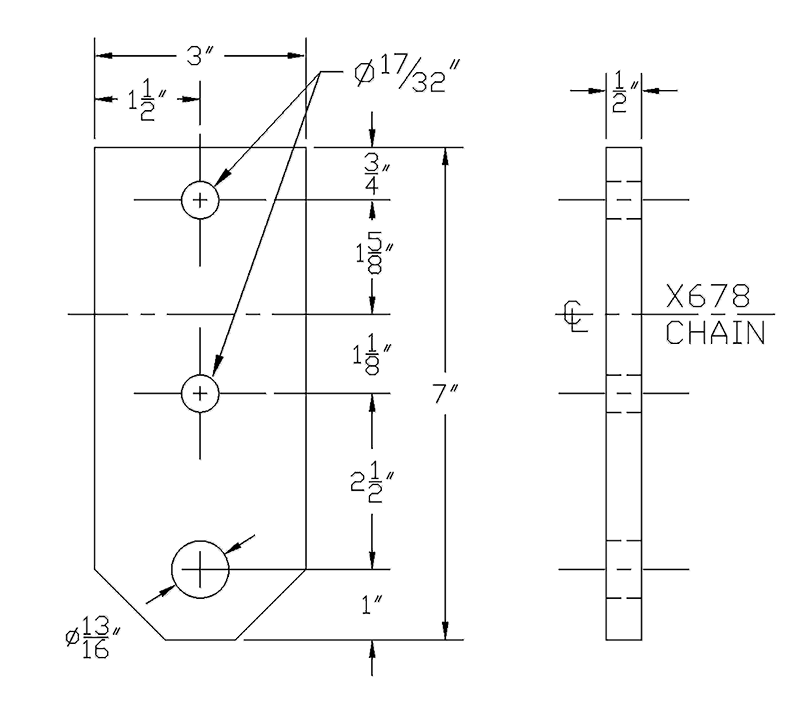

4 Inch Forged Ball Bearing Trolley Assembly

7-3/16″ Drop

8″ Drop

Overview

The 4-inch overhead trolley conveyor is one of the most widely used systems in the industry. Known for its durability, reliability, and versatility, it has become a go-to choice across many sectors. You’ll find it especially common in automotive manufacturing, general assembly lines, and industrial finishing operations. In fact, more miles of this conveyor type are in use today than any other.

Trolley Assemblies

Webb-Stiles 4-inch trolleys are built for strength and longevity. Each unit features heavy-duty forged steel brackets and ball bearing wheels swaged into place for lasting performance.

-

Standard load capacity ranges from 380–400 lbs per trolley

-

At slow speeds with no vertical curves, trolleys can carry up to 500 lbs each

-

For heavier loads, using a two-trolley load bar assembly helps distribute weight evenly

Track & Chain Compatibility

Webb-Stiles 4-inch trolleys run on 4-inch I-beam track and are compatible with 7.7 lbs/ft high-carbon rolled steel. Two standard drop sizes are available to match existing systems:

Note: “Drop” is measured from the top of the track to the centerline of the chain.

-

7-3/16″ drop (short)

-

8″ drop (long)

These trolleys mount to X-458 rivetless chain at 8″ centers or in multiples up to 32″.

-

Spacing beyond 32″ is not recommended due to potential chain sag

-

Intermediate trolleys with Dummy attachments help support the chain when wider spacing is required

Construction & Attachments

All 4-inch systems use X-458 chain as standard.

-

Brackets and attachments are bolted tightly to the center link to reduce wear

-

A shrouded bracket head protects the chain and built-in grease fitting from impact

The standard wheel is the Full Complement – Sealed type, selected for long service life and minimal maintenance. However, other configurations are available upon request.

Attachment Options Include:

- “H” type (standard)

- Pendant

- Load Bar

- Dummy

4″ Trolley Wheels

Retainer Type – Sealed

Full Complement – Sealed

Full Complement – Open

| Type | Use Case | Description | Heat Rating |

|---|---|---|---|

| Retainer Type – Sealed | General use | Two-piece ball bearing with steel retainer. Self-purging, triple labyrinth seals. Re-lubrication port. | Up to 325°F |

| Full Complement – Sealed | Dirty environments / delivery conveyor | One-piece design with no retainer. Triple labyrinth seals. Self-purging grease seal. | Up to 500°F |

| Full Complement – Open | Corrosive / high-temp environments | No seals or plugs. Ideal for systems using spray mist oilers. Optional front/rear seals. | Up to 500°F |

Note: These options represent standard applications. Additional designs and seal types available for special conditions like high heat or contamination.

4″ Trolley Attachments

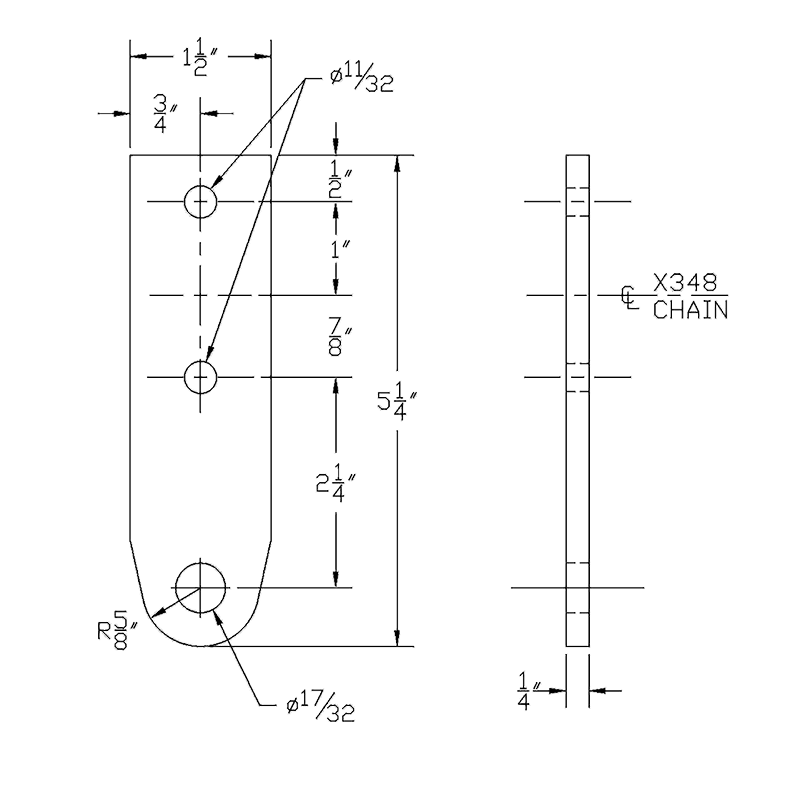

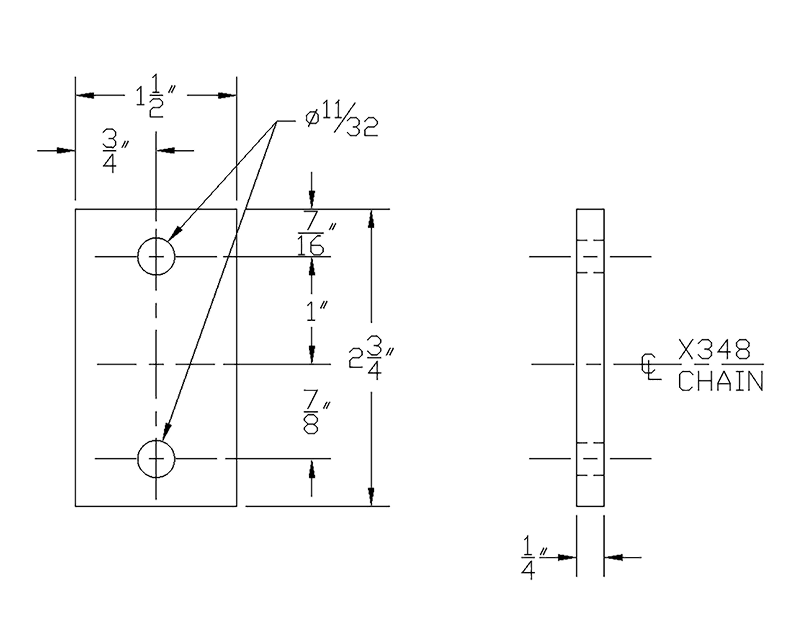

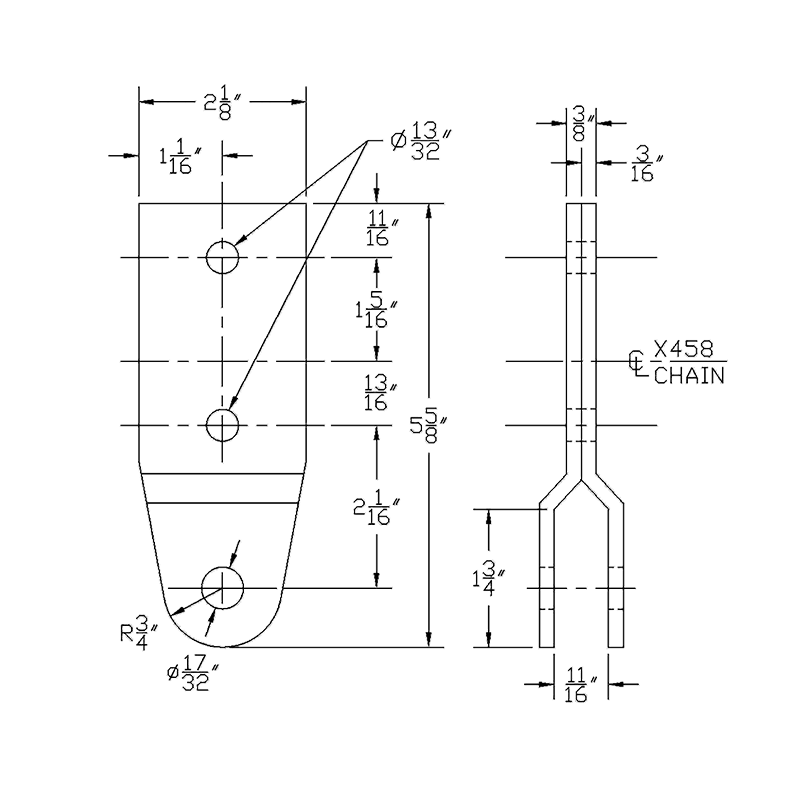

4″ H Attachment

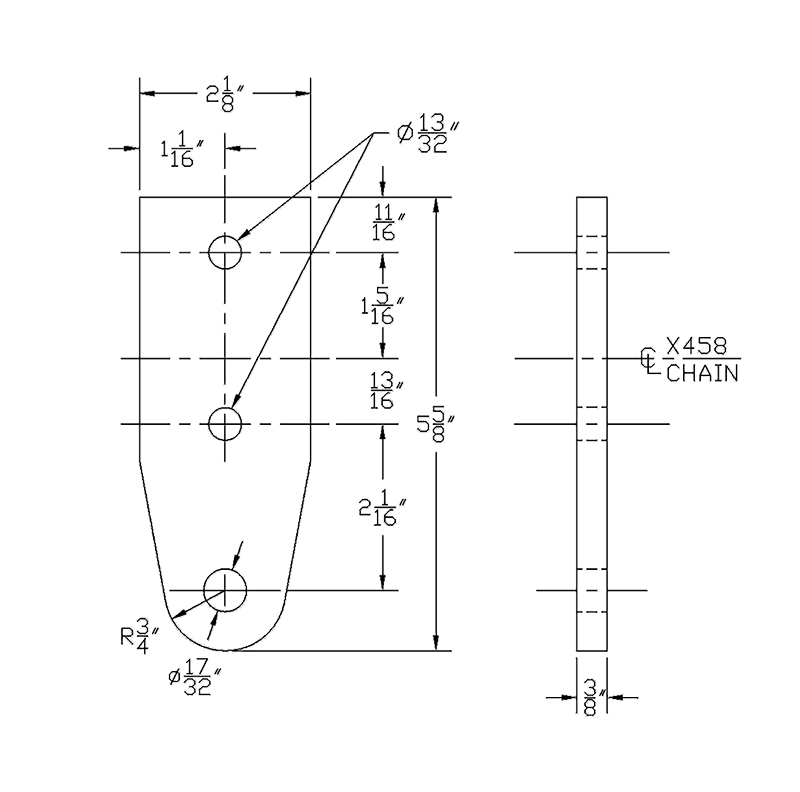

4″ C Attachment

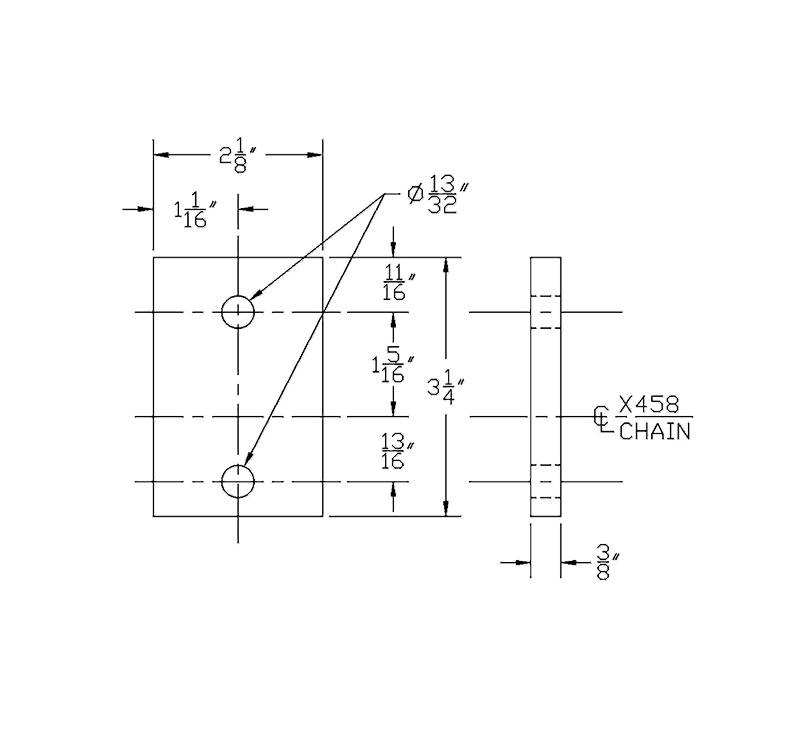

4″ D Attachment

4″ J Attachment

4″ Trolley and Load Bar Assembly

| Attachment Type | Use Case | Notes |

|---|---|---|

| “H” Attachment | Standard / hook suspension | Supplied with all trolleys unless otherwise specified. Commonly used for suspended hooks. |

| “C” Attachment | Light loads / hook or carrier integration | Used when the hook or carrier includes a built-in eye. Supports bent rod hooks. |

| “D” Attachment | Intermediate trolley / long spacing | Dummy-style spacer for support when spacing exceeds 32″. |

| “H-7” Attachment | Rod carrier rotation (1/2″ or 5/8″ rod) | Optional rotating version of the “H” attachment. Specify rod diameter when ordering. |

| Trolley + Load Bar Assembly | Heavy individual loads using two trolleys | Includes load bar, spherical washers, nuts, and “B” attachment connectors for dual mounting. |

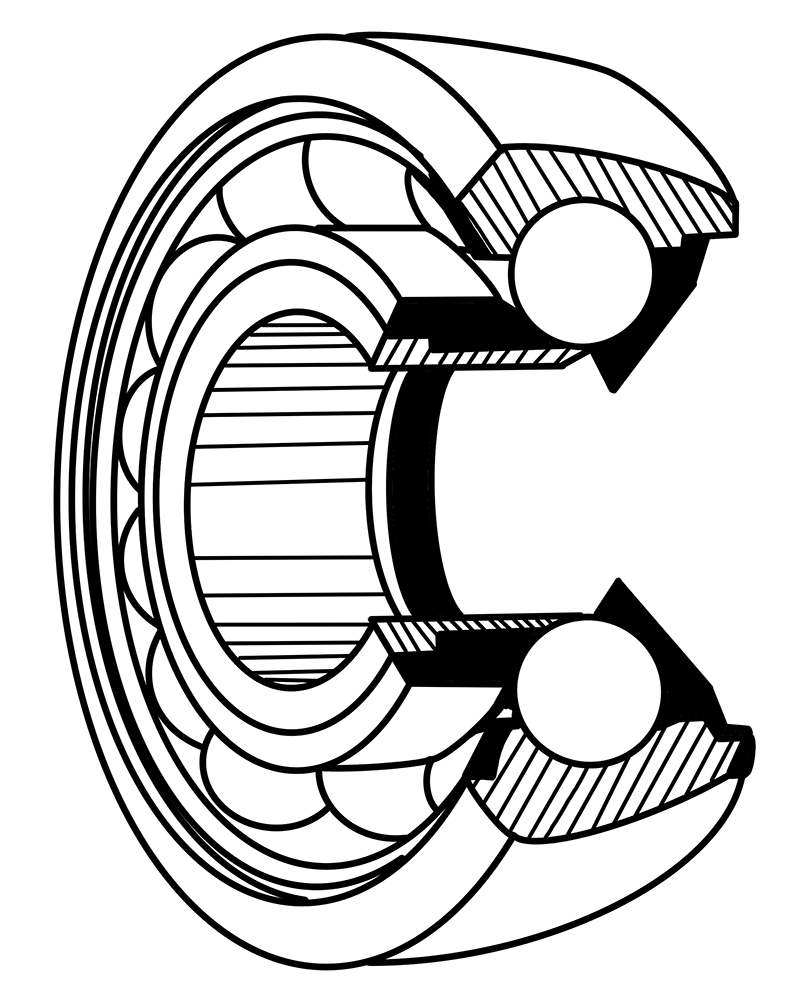

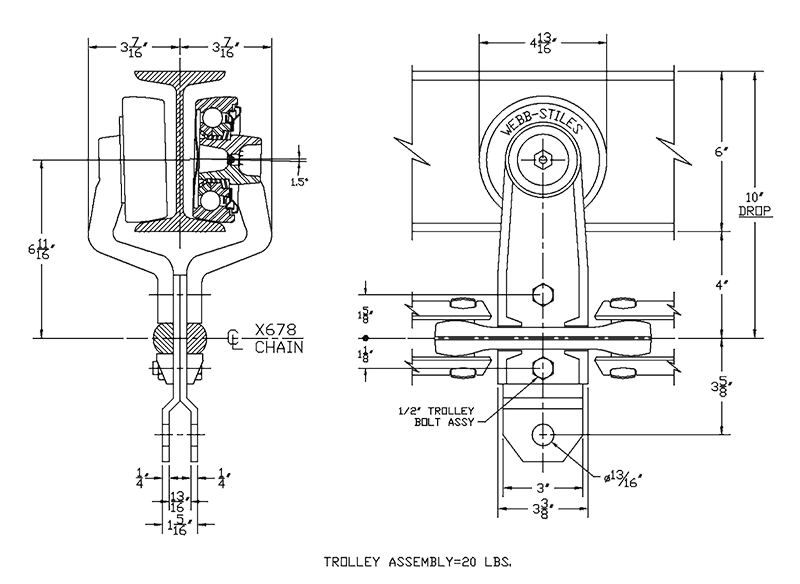

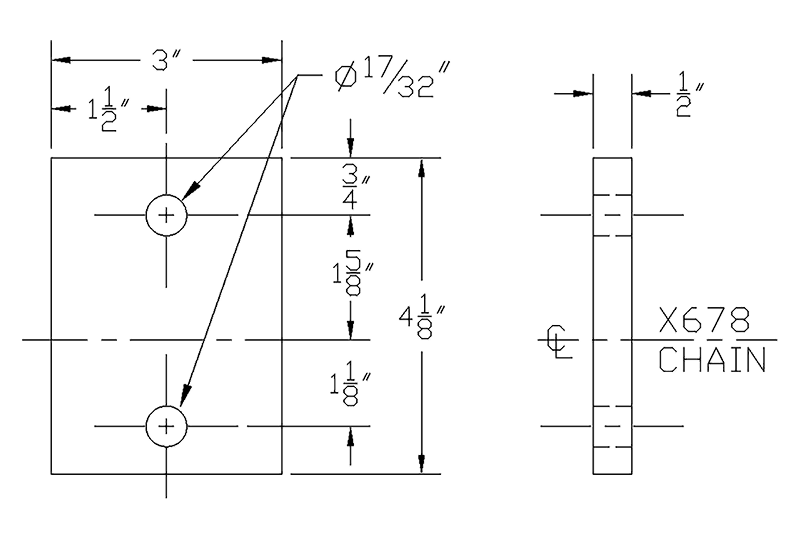

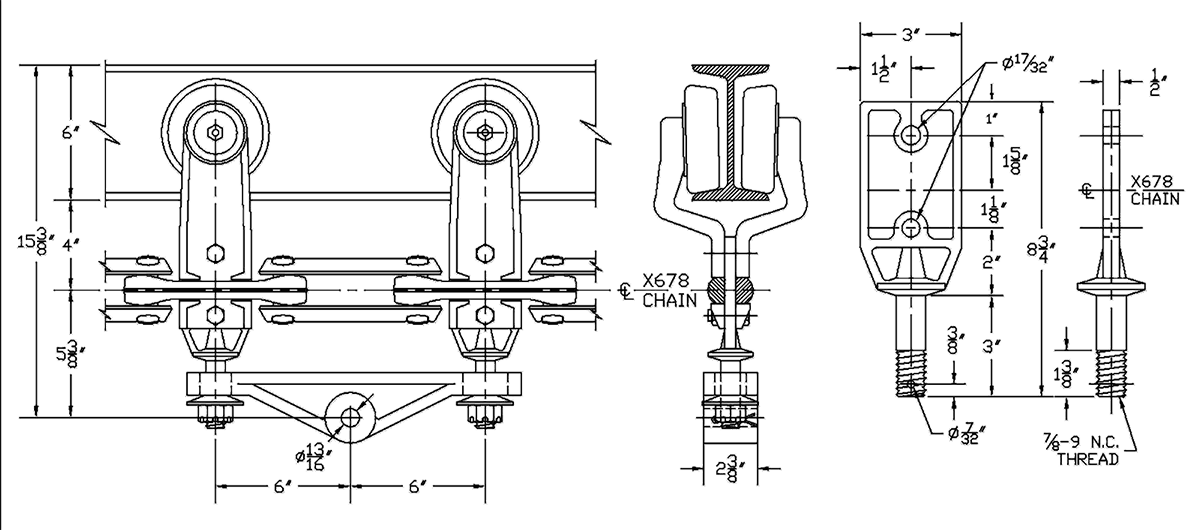

6 Inch Forged Ball Bearing Trolley Assembly

Heavy-Duty Performance

The 6-inch overhead trolley system is built for extreme-duty applications. Each trolley supports up to 1,200 lbs, making it ideal for high-capacity, demanding environments.

This robust design delivers long-lasting reliability while minimizing wear on both the track and conveyor components.

Track & Chain Compatibility

Trolleys operate on X-678 rivetless chain with standard spacing at 12″, 24″, or 36″ centers.

Wider spacing is not recommended, as it may affect stability and increase chain sag.

Final spacing should be determined based on the trolley load, curve radius, and elevation changes in the system layout.

Construction & Attachments

Brackets and attachments bolt securely to the center link of the X-678 chain, forming a strong, reliable connection.

Heavy-duty side pads resist wear, while a shrouded bracket head protects the grease fitting from damage.

The standard trolley wheel is the Full Complement – Sealed type. Other wheel configurations are available upon request.

The default attachment is the “H” (hook-style) type. Pendant, Load Bar, and Dummy attachments are also available, depending on your system needs.

6″ Trolley Wheels

Full Complement -Sealed

Full Complement – Open

| Type | Use Case | Description | Heat Rating |

|---|---|---|---|

| Full Complement – Sealed | General Use | Standard trolley wheel for general applications. Features a full complement of large, precision-ground steel balls with no retainer. Includes all-metal triple labyrinth seals that form a self-purging, triple grease seal. Side-arm grease fitting for relubrication. High-temp grease available. | Up to 500°F |

| Full Complement – Open | Corrosive or High-Temperature Environments | Designed for corrosive or high-temp applications. Uses large precision-ground steel balls with no retainer. Available with front or rear seals or Welch plug. Best used with automatic spray mist oilers to flush bearings with light oil. | Up to 500°F |

Note: Trolley wheels shown represent the most commonly used options for standard applications. A wide range of other designs and seal configurations is available for special environments involving elevated temperatures or contaminants. Consult Webb-Stiles for application-specific recommendations.

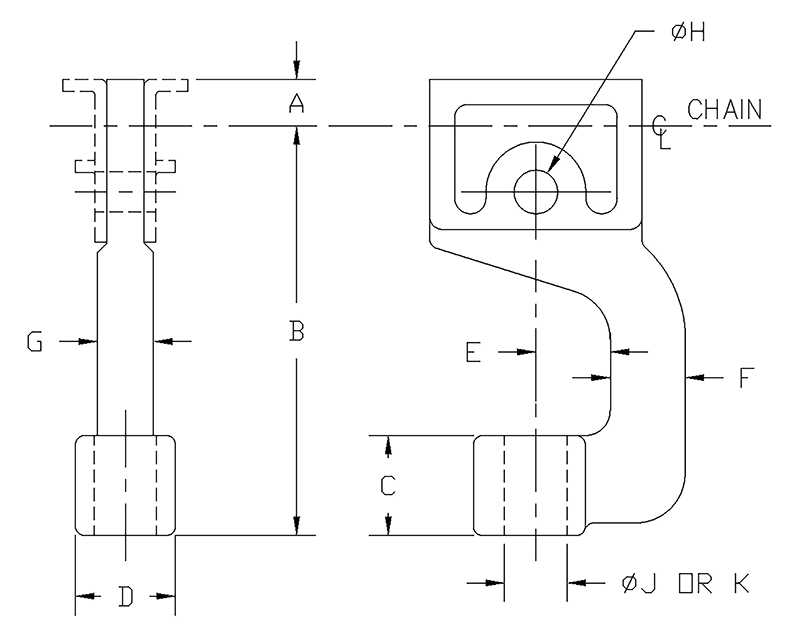

6″ Trolley Attachments

6″ H Attachment

6″ C Attachment

6″ D Attachment

6″ Trolley and Load Bar Assembly

| Type | Use Case | Description |

|---|---|---|

| H Attachment | Clevis: Standard Option | Standard “H” (Clevis) attachment supplied with all trolley assemblies unless otherwise noted. Commonly used to suspend hooks or fittings. Clevis pin not included. |

| C Attachment | Clevis Hook or Carrier: Light Loads | Optional “C” (Pendant) attachment for applications where the clevis is part of the hook or carrier. Also accepts part rod hooks for suspended light loads. |

| D Attachment | Chain: Trolley Spacing Exceeds 36 Inches | Optional “D” (Dummy) attachment used as a spacer with intermediate trolleys to support the chain between loads or when spacing exceeds 36 inches. |

| Trolley & Load Bar Assembly | Two Trolley: Heavy Load | Optional assembly for heavier individual loads using two trolleys. Includes load bar, spherical washers, nuts, and “B” attachments for secure connection. |

Not Sure Which Components Fit Your System?

Our sales engineers can help you choose the right trolleys, attachments, and chain spacing for your overhead conveyor. Whether you’re upgrading, replacing, or starting from scratch — we’re here to help.