Slat Conveyors by Webb-Stiles

What is a Slat Conveyor?

Slat conveyors are material handling systems that use flat slats—made from steel, hardwood, or plastic—mounted to a moving chain. In many facilities, slat conveyors serve as a primary link between workstations, enabling steady flow and reducing transfer points. These slats form a continuous, stable surface ideal for transporting a wide variety of products. This is especially useful for items that are too irregular, hot, or heavy for traditional belt or roller conveyors.

Because the slats move as a unified surface, they can easily handle items with uneven bases, sharp edges, or high heat—without damaging the conveyor or the product. As a result, slat conveyors are often chosen for manufacturing lines where durability, product support, and precise control matter most.

At Webb-Stiles, our slat conveyors handle loads of 10,000 pounds or more and integrate smoothly with computer-controlled start/stop systems. These features support indexing, accumulation, and staged movement. Additionally, we either build every system from your print or fully engineer it to match your layout and process.

History of the Slat Conveyor

Slat conveyors originated as a practical solution for moving heavy or irregularly shaped loads that couldn’t be handled easily by rollers or belts. As manufacturers looked for alternatives to rollers and belts, slats offered a practical path forward—especially in industries that required surface stability and strength. In the early-to-mid 20th century, manufacturers began using a series of metal or wooden slats attached to a chain. This created a flat, durable surface capable of supporting a wide range of products.

Their design made them ideal for applications where loads required stable support—such as engine blocks, machinery components, or large assemblies. In these scenarios, slat conveyors provided a smooth, controlled means of moving products through assembly lines, paint booths, and processing areas where cleanliness, stability, and heavy load capacity were essential.

Over time, materials evolved from wood to steel and synthetic slats. This shift improved durability while reducing maintenance. Today, slat conveyors remain a reliable option in manufacturing environments that demand consistent handling of heavy or awkward products—particularly in automotive, appliance, and general assembly industries.

Types of Slat Conveyors

Slat conveyors are highly configurable systems. While the overall design remains consistent—a flat slat surface that a chain drives—the specific construction can vary based on the product, environment, and application. Below are the most common variations:

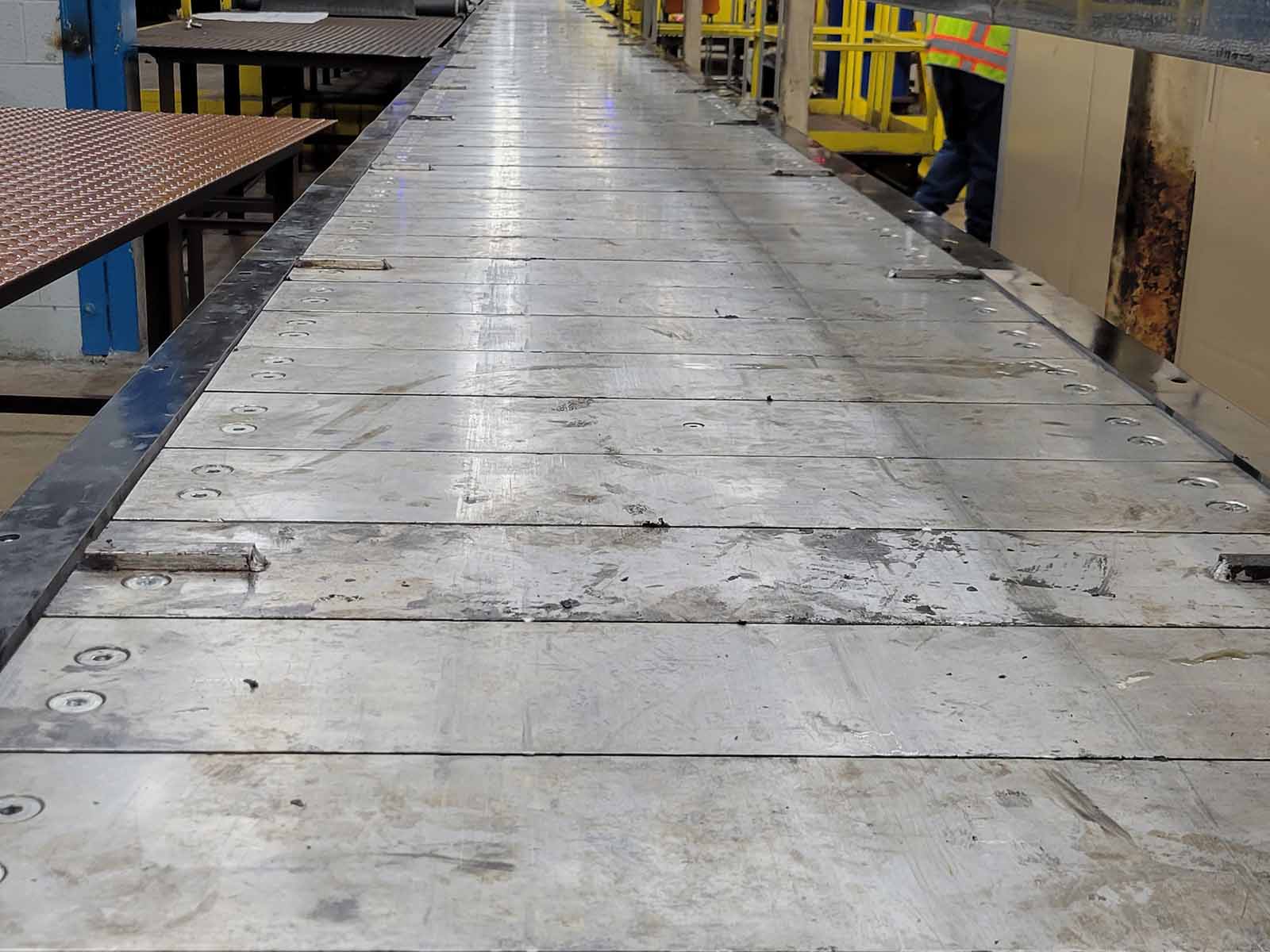

Steel Slats

Steel slats offer high durability and perform well in harsh conditions. They’re ideal for handling hot, abrasive, or heavy products without deforming. Depending on contact needs, the surface can be smooth or textured. Additionally, steel slats often pair with return rollers or roller beds for added flexibility.

Best for: Heavy-duty use, high temperatures, and rugged production environments.

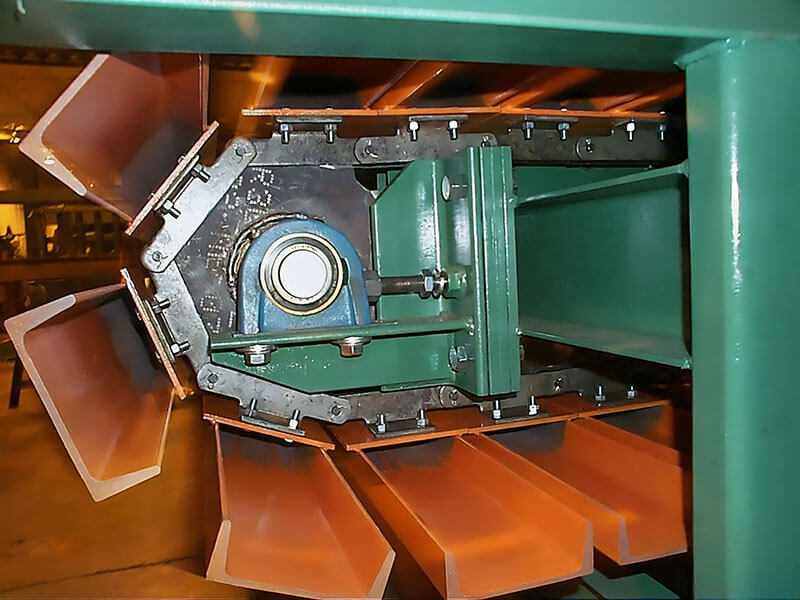

Formed or Structural Channel Slats

Channel-style slats provide extra reinforcement and structural depth. For this reason, they’re well-suited for applications where added rigidity is needed, or when slats must serve dual purposes—such as supporting both the load and onboard tools.

Best for: High-load applications with large or unevenly distributed weights.

Hardwood Slats

Hardwood slats create a stable surface while minimizing product damage. They are frequently chosen for assembly lines or workstation-integrated layouts. Because they absorb impact, hardwood slats offer a smoother ride—especially for painted or delicate products.

Best for: Sensitive loads, assembly lines, or environments where steel would damage the product.

Return Slat Configurations

Some layouts use enclosed return paths as a platform for staging parts or supporting utility lines. In these cases, slats run beneath a sheeted top surface that holds containers, tools, or supplies. As a result, this setup maximizes floor space without interfering with conveyor function.

Best for: Space-conscious lines that benefit from combining product transport with workstation support.

Slats with Fixtures or Guides

You can mount fixtures, dividers, or guides directly to the slats to keep parts aligned during transit. This is especially valuable in operations with robotic interaction, manual tooling, or movement between multiple stations. Moreover, we customize slats for precise part orientation and handling.

Best for: Precision part handling, robotic stations, or processes with built-in stops and starts.

Applications & Uses

Slat conveyors perform best when belts or rollers can’t offer the support, durability, or control your product needs. For example, they excel with sharp-edged castings, painted parts, or staged subassemblies—any item that demands stable handling.

Because of this flexibility, Webb-Stiles has engineered slat conveyors across a wide range of industries and production layouts:

Appliance Manufacturing

-

Fixtures hold refrigerator doors during assembly

-

Integrated air lines and tool stations support operator workflows

-

We enclose return slats with sheet metal to support tool lines or part staging above

-

You can add ball-transfer tables for inspection loops

Heavy Industry & Assembly

-

Steel and channel slats carry 10,000 lb containers

-

We use transition rollers to handle heavy pallets

-

Hardwood and oak slats minimize product damage in high-impact zones

-

We design slats with removable guards for ergonomic access

Custom & Mixed-Use Lines

-

Plastic slats transport small components like gears and trunnions

-

Built-in guides or fixtures support alignment during movement

-

Narrow conveyors integrated into tight or segmented line layouts

-

Teams design return paths for storage, staging, or service integration

Key Features

Slat conveyors from Webb-Stiles are built to carry more than just weight. In fact, they offer long-term durability, part control, and layout flexibility—whether you’re working in heavy industry or a mixed-use assembly environment.

Built for Weight and Wear

-

These systems handle loads exceeding 10,000 lbs without deflection

-

We offer slats in steel, hardwood, oak, or plastic.

-

They withstand sharp edges, hot parts, and rugged surfaces

-

“For added strength, you can use structural channel or heavy-duty frames

Flexible Layout Integration

-

Slats run in straight lines, workstation loops, or curved paths depending on the layout

-

Sheeted return paths support tool lines or part staging without obstruction

-

For example, slats may interface with ball tables, lift zones, or transfers

-

In many cases, these systems work as standalone conveyors or within a larger material handling line

Configurable for Part Control

-

Fixtures and guides can be built into slats for product alignment

-

Systems allow for narrow or wide-bed configurations based on part geometry

-

Slat pitch, thickness, and clearance can be adjusted to fit your application

-

In addition, optional guard panels help protect operators or improve access

Engineered to the Job

-

Webb-Stiles builds systems to print or develops them as full turn-key solutions.

-

They’re available with indexing, accumulation, or start/stop control

-

Each system supports air tool lines, sensors, or manual workstations—depending on your workflow

-

Most importantly, every system is designed around your product—not from a standard template

How Slat Conveyors are Engineered

Slat conveyors aren’t just about transporting product—they’re about how that product is supported in motion. Every system starts with a clear understanding of what’s being moved, how it needs to travel, and what interaction happens along the way.

Support, Fixtures, and Product Fit

Some products sit flat on a slat surface. Others require guides, dividers, or custom fixtures built directly into the conveyor. The shape, stability, and contact points of your product drive everything from material choice to slat construction and pitch.

Layout and Line Behavior

Straight runs, workstation loops, elevation changes—the conveyor’s path and layout drive key decisions about navigation and workspace interaction. Teams might expose return paths, enclose them, or repurpose them for tool access. Motion isn’t always continuous; systems can stop, start, index, or accumulate depending on the flow of production.

Process Integration

Slat conveyors don’t operate in isolation. Instead, they often interact with air lines, sensors, tools, or manual workstations. Whether you need basic control or tight synchronization with your process, we build the system around how work gets done.

Ultimately, every decision—frame design, chain drive, slat spacing—comes from understanding your part, your process, and the floor it moves across. That’s where Webb-Stiles starts.

Downloads & Literature

Slat conveyors are a key part of our broader chain-driven conveyor solutions. As such, they often serve as the foundation for custom system layouts.

For more detail, the brochure above includes slat system configurations, material options, load specs, and integration examples.

Ready to talk through your system?

Contact our team to start a conversation about your application, layout, or product support needs.